Custom Vacuum Bags

Vacuum Bags, also known as decompression packaging bag, is the packaging container of air all out of the seal, maintain the bag in a highly decompressed state, the air is scarce equivalent to the effect of low oxygen, so that micro-organisms do not have conditions of survival, in order to achieve the purpose of fresh food, no disease and rot occurrence.

Applications include vacuum packaging in plastic bags, aluminium foil packaging, glassware, plastic and its composite packaging. Packaging materials can be selected according to the type of article. As the fruit is fresh food, still in respiration, a high degree of oxygen deprivation will cause physiological disease, therefore, the use of vacuum packaging of fruit is less.

Packaging in vacuum bags not only protects food or other application frommoisture, but allows food retailers to display their product in anattractive manner that allows buyers to clearly see what they aregetting. Keeping food fresh at all times will minimize spo.These really contemporary design vacuum bags are the ultimate choice for those perfect Fresh keeping. Your brand name can and logo can easily be printed on these vacuum bags. Bring life to the look of the contents with this elegant packaging design and also reduce the carbon imprint because the materials are made with poly or other biodegradable sources. Need a custom packaging product in a unique style or size? Do you have a large volume requirement? We have an entire department dedicated to locating and developing unique products that exactly meet your most demanding packaging requirements.Our high-quality vacuum bag ship in as little as 2-3 weeks, with no minimum order quantity.

-

PE Biodegradable Material PET Poop Bags

-

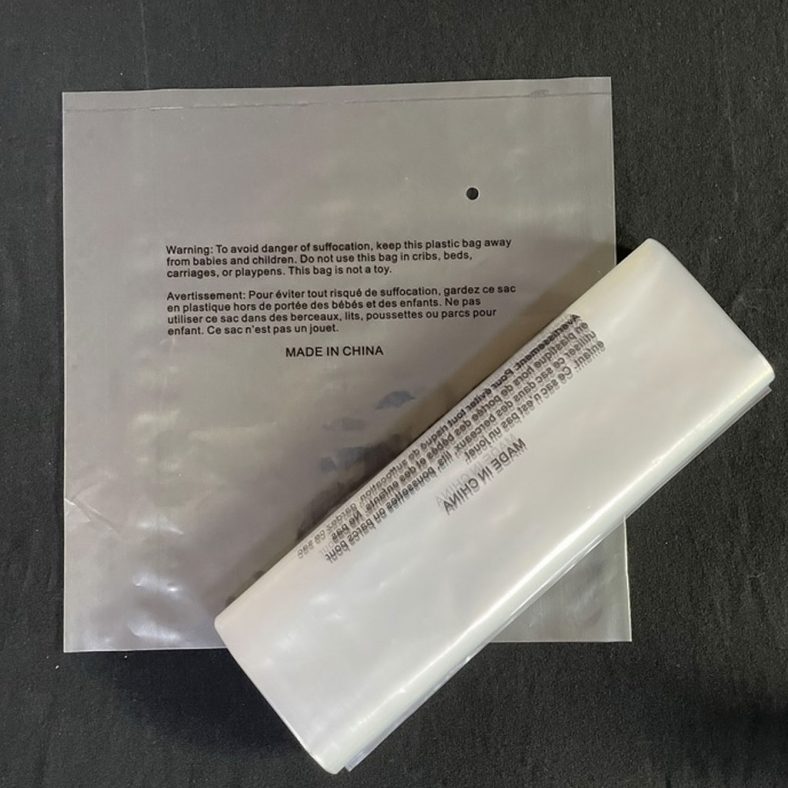

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

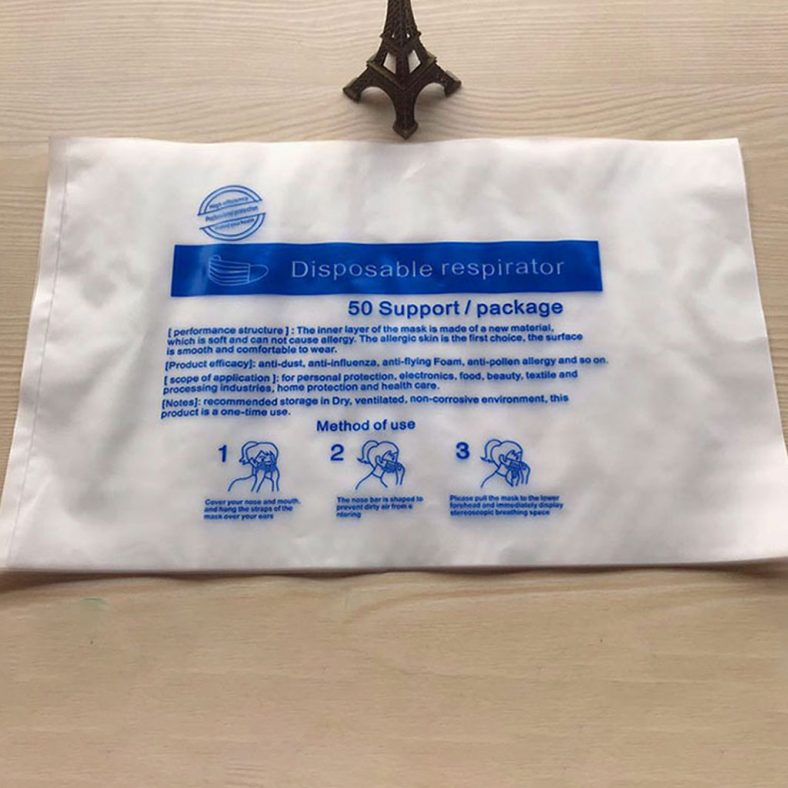

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

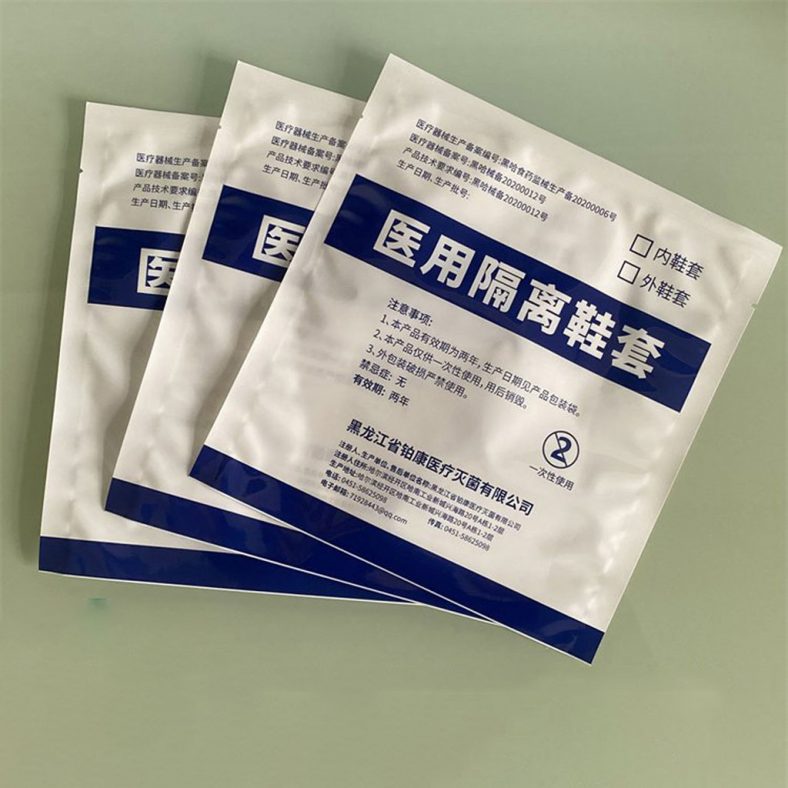

Self Sealing Bag For Medical Shoe Cover

The term vacuum, translated from the Latin vacuo, means nothingness. In fact, a vacuum should be understood as a space where the gas is thin. A state of gas below an atmospheric pressure in a given space is collectively referred to as a vacuum. The degree of thinness of the gas in a vacuum is called degreeofvacuum and is usually expressed as a pressure value. Therefore, vacuum packaging is not actually a complete vacuum, the vacuum in the food container using vacuum packaging technology is usually in the range of 600-1333 Pa. Therefore, vacuum packaging is also known as decompression packaging or exhaust packaging.

The Mechanism Of Vacuum Bag

- It is to reduce the oxygen content of the packaging, to prevent mould and rot of packaged food, to maintain the colour and aroma of food, and to extend the shelf life.

- Vacuum packaging in food certainly has an important role. But it is used in the processing of clothing items have the same extraordinary effect.

- Vacuum packaging compared to ordinary packaging methods, it reduces the space occupied by the goods. And has the advantages of moisture, dust and bacteria, so that clothing items are more convenient when transported.

- Greatly reducing the possibility of loss caused by certain accidents.

The Concept Of Vacuum Bag

Vacuum packaging is packaging that protects products from environmental contamination and extends the shelf life of food and other products, increasing their value and quality. Vacuum packaging technology originated in the 1940s. Since 1950, polyester and polyethylene plastic films have been successfully used in the packaging of goods, vacuum packaging machines have been rapidly developed.

A wide range of plastic vacuum packaging abounds in people’s lives and workplaces. Lightweight, airtight, fresh, anti-corrosion and rust-proof plastic vacuum packaging is used in a wide range of applications, from food to pharmaceuticals and knitwear, from precision product manufacturing to metalworking plants and laboratories. The growing use of plastic vacuum packaging has driven the development of plastic vacuum packaging machines and has placed higher demands on them.

The mechanism of vacuum packaging: its purpose is to reduce the oxygen content of the package, to prevent mold and rot of packaged food, to maintain the colour and flavor of food, and to extend the shelf life.

The Role Of Vacuum Bag

- The main role of vacuum packaging is to remove oxygen, in order to help prevent food spoilage, its principle is also relatively simple, because food mould and spoilage is mainly caused by the activities of micro-organisms, and most micro-organisms (such as mould and yeast) is the survival of the need for oxygen, and vacuum packaging is the use of this principle, the bag and food cells within the oxygen pumped away, so that micro-objects lost “living The vacuum packaging uses this principle to remove the oxygen from the bag and from the food cells, depriving the micro-organisms of their “living environment”. Experiments have shown that when the concentration of oxygen in the bag is less than 1%, the growth and reproduction rate of microorganisms drops sharply, and when the concentration of oxygen is less than 0.5%, most microorganisms will be inhibited and stop reproducing. (Note: Vacuum packaging cannot inhibit the growth of anaerobic bacteria and enzymatic reactions that cause food spoilage and discolouration, so it needs to be combined with other auxiliary methods such as refrigeration, quick-freezing, dehydration, high-temperature sterilisation, irradiation sterilisation, microwave sterilisation, salt pickling, etc.)

- In addition to inhibiting the growth and reproduction of micro-organisms, another important function of vacuum deoxidation is to prevent the oxidation of food. Therefore, in addition to oxygen can effectively prevent food deterioration, maintain its colour, aroma, taste and nutritional value.

- The main role of vacuum inflatable packaging in addition to the vacuum packaging has the function of oxygen preservation, there are mainly anti-pressure, gas barrier, freshness, etc., can more effectively make the food long-term to maintain the original colour, aroma, taste, shape and nutritional value. In addition, there are many foods that are not suitable for vacuum packaging and must be used vacuum inflatable packaging. Such as brittle and fragile food, easy to lump food, easy to deformation away from the oil food, there are sharp edges or high hardness will pierce the bag of food. Food by vacuum inflatable packaging, the bag inflatable pressure is greater than the atmospheric pressure outside the bag, can effectively prevent the food pressure broken deformation and does not affect the appearance of the bag and printing decoration.

Vacuum inflatable packaging in the vacuum and then filled with nitrogen, carbon dioxide, oxygen, a single gas or a mixture of two or three gases. Its nitrogen is an inert gas, filling the role of the bag to maintain positive pressure, to prevent the air outside the bag into the bag, the food to play a protective role. Its carbon dioxide can be dissolved in various types of fat or water, leading to a weak acidic carbonic acid, which has the activity of inhibiting microorganisms such as moulds and spoilage bacteria. Its oxygen has the ability to inhibit the growth and reproduction of anaerobic bacteria, keeping the freshness and colour of fruits and vegetables, and high concentrations of oxygen can make fresh meat keep its bright red colour. The freshness of the fruit and vegetables but the nutrition is not lost.

The Principle Of Vacuum Bag

One of the important aspects of vacuum packaging is the removal of oxygen, which helps to prevent food spoilage, and its principle is relatively simple, because food mould deterioration is mainly caused by the activities of micro-organisms, and most micro-organisms (such as mould and yeast) need oxygen to survive, and vacuum packaging is the use of this principle, the bag and the food cells within the oxygen pumped away, so that micro-organisms lose ” living environment”. Experimental evidence: when the concentration of oxygen in the bag ≤ 1%, the growth and reproduction rate of microorganisms will drop sharply, oxygen concentration ≤ 0.5%, most microorganisms will be inhibited and stop reproducing. (Note: vacuum packaging can not inhibit the reproduction of anaerobic bacteria and enzymatic reactions caused by food deterioration and discolouration, so it is also necessary to combine with other auxiliary methods, such as refrigeration, freezing, dehydration, high temperature sterilization, irradiation sterilization, microwave sterilization, salt pickling, etc..

In addition to inhibiting the growth and reproduction of micro-organisms, another important function of vacuum de-oxygenation is to prevent oxidation of food, as fats and oils contain a large amount of unsaturated fatty acids, which are oxidised by the action of oxygen, causing the food to become tasteless and spoiled. In addition, oxidation causes the loss of vitamin A and vitamin C. Unstable substances in food colouring are affected by the action of oxygen, causing the colour to darken. Therefore, oxygen removal can effectively prevent food spoilage and maintain its colour, aroma, taste and nutritional value.

A variant of vacuum packaging is inflatable packaging. The main role of inflatable packaging in addition to the vacuum packaging has the function of oxygen preservation, there are mainly anti-pressure, gas barrier, freshness, etc., can more effectively make the food long-term to maintain the original colour, fragrance, taste, shape and nutritional value. In addition, there are many foods that are not suitable for vacuum packaging, but must be used inflatable packaging. Such as brittle and fragile food, easy to caking food, easy to deformation away from the oil food, sharp edges or high hardness will pierce the bag of food, etc.. Food by the food vacuum packaging machine pumping packaging, filled with some gas, so that the inflatable pressure inside the bag is greater than the atmospheric pressure outside the bag, can effectively prevent the food pressure broken deformation, and does not affect the appearance of the bag and printing and decoration.

Inflatable packaging in the vacuum and then filled with a single gas such as nitrogen, carbon dioxide, rare gases or a mixture of 2-3 gases. Nitrogen is a chemically stable gas, which protects the goods from oxidation and other external disturbances, and keeps the bag under positive pressure to prevent the packaging from being flattened to the point of damage to the goods. Carbon dioxide can dissolve in various types of fat or water to form a less acidic carbonic acid, which has the activity to inhibit micro-organisms such as mould and spoilage bacteria. The principle of rare gases is similar to that of nitrogen.

The Selection Of Vacuum Bag

Vacuum packaging machine variety, in the selection should focus on the following factors.

- Packaging speed. For the consideration of improving production efficiency, you can choose a double or multi-chamber vacuum packaging machine to improve the overall production progress.

- Whether the packaged goods need to be filled with other protective gases. Multifunctional vacuum packaging machines with inflatable devices can be selected.

- The requirements of the vacuum level of the packaged goods. If the packaged goods need to be kept intact under high vacuum conditions, choose a chamber vacuum packaging machine.

- The requirements of the vacuum packaging machine for the composition state of the packaged goods.

When purchasing, packaging solids, granules and other dry and non-corrosive materials, you can choose aluminum alloy, while packaging with soup, salt, acid composition of high materials, you can choose stainless steel or aluminum-magnesium alloy material. The sealing ring is generally made of silicone rubber, black rubber, a few low-grade products using foam rubber, silicone rubber high temperature resistance, corrosion resistance, good sealing, long service life, foam rubber sealing is poor, easy to fall off, short service life.

The Application Of Vacuum Bag

- Cured and preserved products: sausage, ham, bacon, duck, etc.

- Sauce and pickled vegetables: squash, dried radish, daikon, kimchi, etc.

- Soybean products: dried bean curd, vegetarian chicken, bean paste, etc.

- Cooked food products: roast chicken, roast duck, soy sauce beef. Deep-fried products, etc.

- Convenience food: rice, instant wet noodles, cooked vegetables, etc.

- Soft canned food: fresh water bamboo shoots, sweetened fruits, eight-jewel porridge, etc.

The Development Prospects Of Vacuum Bag

A brief analysis of the future prospects of vacuum packaging technology.

- First, high efficiency: high productivity vacuum packaging machine production efficiency has developed from several pieces per minute to dozens of pieces, thermoforming – filling – sealing machine production of up to 500 pieces / min or more.Automation: A Japanese company produces the TYP-B series rotary vacuum chamber type packaging machine with a fairly high degree of automation of multiple stations. The machine has two rotary tables for filling and vacuuming. The filling table has 6 stations for bag supply, feeding, filling and pre-sealing until the package is sent to the vacuuming table. The vacuuming rotary table has 12 stations, i.e. 12 vacuum chambers, completing vacuuming and sealing until the finished product is output, the production efficiency can reach 40 bags/min, mainly used for packing soft canned food.

- Second, single machine multi-function: multi-function on a single machine can easily expand the scope of use. To achieve multi-functional single machine must adopt modular design, through the change and combination of functional modules, become suitable for different packaging materials, packaging items, packaging requirements of different types of vacuum packaging machine. Representative products are the German BOSCH company belongs to the HESSER factory production of multi-station bag-making vacuum packaging machine, its bag-making, weighing, filling and vacuuming, sealing and other functions can be completed in a single machine.

- Three, grouping production line: the composition of the production line when the need for more and more functions, all the functions will be concentrated in a single machine will make the structure very complex, operation and maintenance is also not convenient. At this time, several machines with different functions and matching efficiency can be combined to form a more complete production line. Such as France CRACE-CRYOYA and ISTM company developed fresh fish, vacuum packaging production line and Sweden Shuyhong International Ltd. and the Swedish Textile Research Institute developed a textile vacuum packaging system.

- Fourth, the use of new technologies: in the packaging method, a large number of inflatable packaging instead of vacuum packaging, the inflatable components, packaging materials and inflatable packaging machine research closely integrated; in the control technology, more applications of computer technology and microelectronics; in sealing, the application of heat pipe and cold sealing technology; advanced devices installed directly on the vacuum packaging machine, such as the installation of computer-controlled coarse grains high precision combination scales; on rotary or vacuum packaging machines, the application of advanced high speed circular surface cam indexing machinery, etc. All these new technologies are used to make the vacuum packaging machine more efficient and intelligent.

Vacuum packed products have been widely used in people’s life. Vacuum packed products have many advantages, such as preservation of quality and freshness, anti-corrosion and rust, small space occupation, easy to carry, etc. Vacuum packaging is widely used and has penetrated into all walks of life, and is welcomed by everyone!

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.