Custom Shopping Bags

Shopping bags, as the name suggests, are bags that are used for shopping, and the main shopping bags available on the market are: plastic shopping bags, non-woven shopping bags, paper shopping bags, cotton and linen shopping bags, etc.Today’s society pursues a low-carbon and low-pollution lifestyle, due to the increase in population, the demand for shopping bags is also increasing, given that it will cause a lot of pollution, nowadays, environmentally friendly shopping bags have been used.Custom manufacturer of shopping bags. Recyclable and compostable paper shopping bags are offered. Reusable and biodegradable canvas tote bags are provided. Gift and garment bags are also offered. Other services include packaging, warehousing, distribution and shipping. Suitable for retail and packaging applications.

Contract manufacturer of Shopping bags, which can be made from polyethylene plastic,Nonwoven,Paper ,Cotton And Linen ,Waste Paper and other materials. Capabilities include radio frequency (RF) welding, industrial sewing, product design, embroidery, screen and digital printing. Bags can have grommet and zipper closures. Suitable for handling hazardous substances, including nuclear, medical and plant waste. Serves the agriculture, manufacturing, recreation, transportation, medical, military and aerospace industries.No matter what size shopping bags you need, Wonder Plastic can custom manufacture the solution that perfectly suits your existing shopping bags.

-

PE Biodegradable Material PET Poop Bags

-

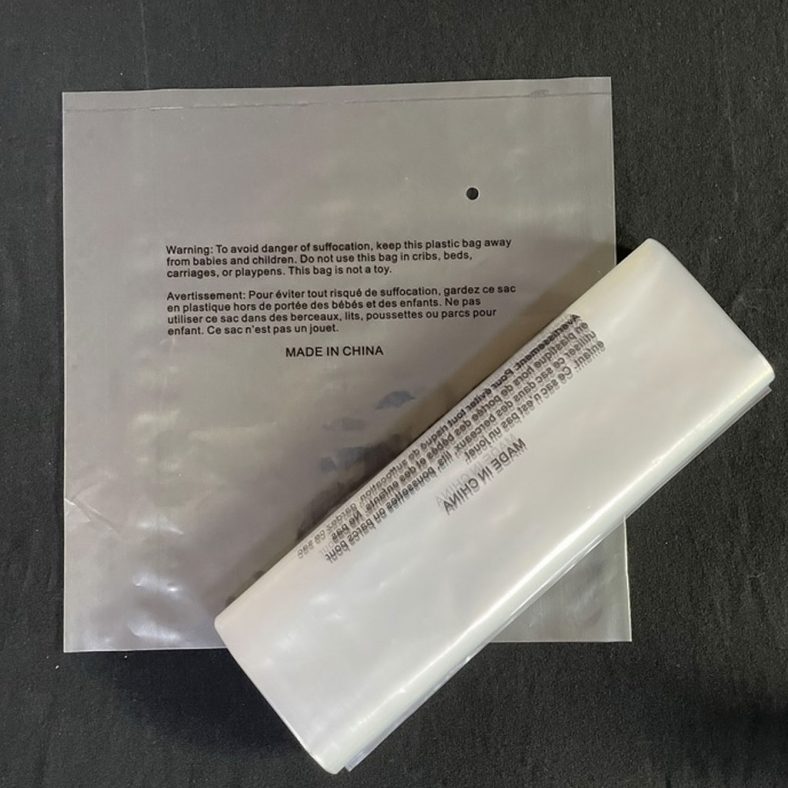

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

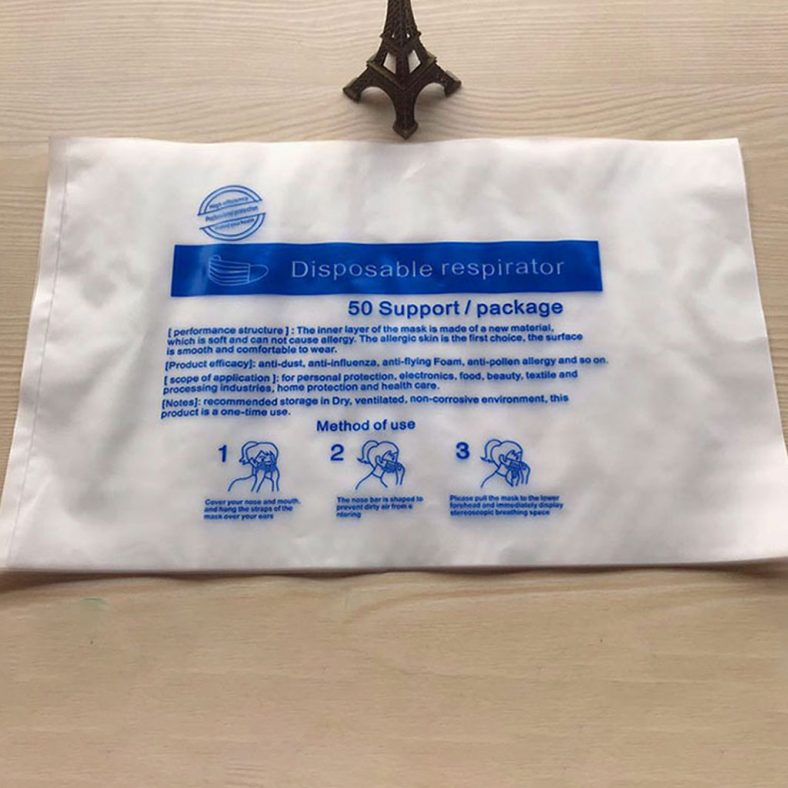

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

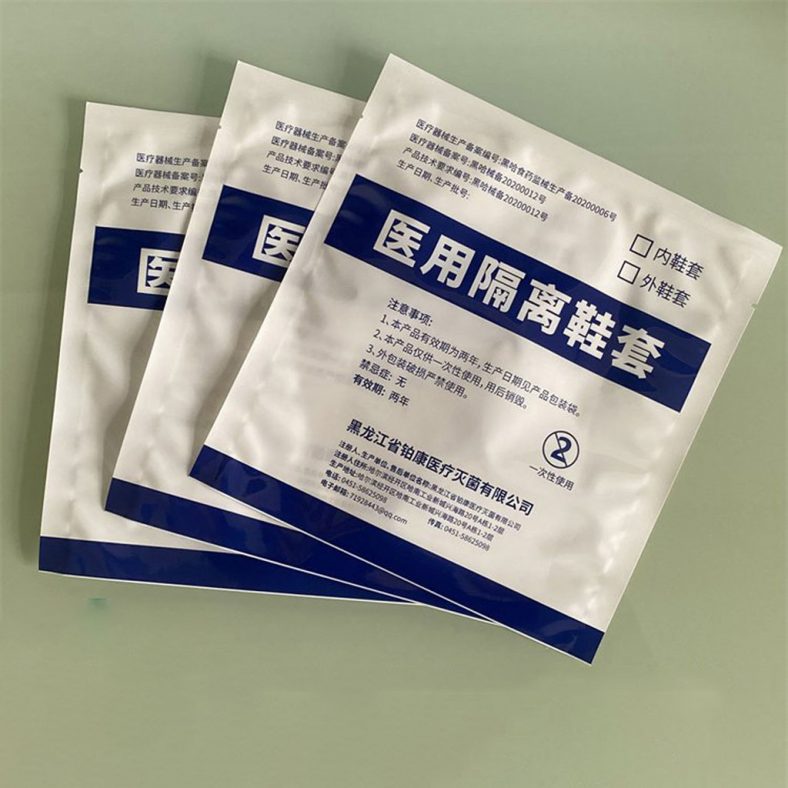

Self Sealing Bag For Medical Shoe Cover

Shopping bags are bags that are used to carry purchases made at a store or market. They can be made of various materials such as paper, plastic, or cloth, and are typically provided by the store at the point of sale for customers to use to carry their purchases home. Shopping bags can be reusable, meaning that they can be used multiple times, or they can be disposable, meant to be used once and then discarded. Some shopping bags have handles or straps for carrying, while others have a more complex design, such as a shoulder strap or backpack style. Some shopping bags are designed to be more environmentally friendly, such as those made of recycled materials or those that can be easily recycled or composted after use.

Plastic Shopping Bags

Plastic shopping bags are packaging materials made from polyolefins as the main raw material, with other substances added as appropriate. The use of polyolefin is mainly polyethylene class (PE), commonly known as soft rubber, the main products include low density polyethylene or high pressure polyethylene (LDPE), high density polyethylene or low pressure polyethylene (HDPE), linear low density polyethylene (LLDPE) and metallocene polyethylene (mLLDPE) four categories. In order to reduce their costs, most companies have added about 30% calcium carbonate made of filled plastic shopping bags, such plastic shopping bags due to incineration in landfills do not emit toxic gases. Just introduced the national plastic shopping bag standards will be divided into three categories of plastic shopping bags as follows.

Ordinary plastic shopping bags – the use of polyolefin and filler as raw materials, such plastic shopping bags do not have degradation properties, abandoned in the field will not degrade. These plastic shopping bags have excellent recyclability and can be recycled many times. The recycled material has slightly reduced performance to varying degrees, but can be used to produce shopping bags or rubbish bags with less demanding performance and less stringent colour requirements. The key issue is whether it can be recycled back.

Starch-based plastic shopping bags – such shopping bags with modified starch as the main raw material, appropriate to add a small amount of other degradable materials to improve its performance. The plastic shopping bags used after abandonment in the field can be naturally degraded.

Degradable plastic shopping bags – these shopping bags are produced from fully degradable plastic and have fully degradable properties. Product abandoned in the field can be completely degraded to small molecules of microorganisms, without any environmental pollution, foreign countries are promoting such plastic shopping bags. In accordance with the specific composition of the fully degradable plastic is different, it can be divided into the following three categories.

- Natural starch as raw material through biofermentation synthesis of PLA, PHA class biodegradable plastics, need to consume a lot of food, so the development space is limited.

- Aliphatic polycarbonate (APC) biodegradable plastics, which are made from carbon dioxide, is a by-product of industry. It does not consume food and can reduce the emission of carbons and eliminate global warming caused by greenhouse gases.

- Adding non-starch degradation agents to ordinary plastics for complete degradation products, in the industrialization stage, if the degradation performance is reliable, very promising development.

Nonwoven Shopping Bags

Paper Shopping Bags

Cotton And Linen Shopping Bags

Waste Paper Shopping Bags

- For general dry goods, it is recommended to use full American or European waste, and to control the production of raw paper according to the technical indicators of A or B grade kraft boxboard. The top layer can be hung or unhung, depending on whether complex patterns and advertisements are to be printed. The weight of the paper sheet can be 135~150g/m2. 25×20×15cm paper bags can bear a weight of 8~15kg.

- For goods that need to withstand a certain amount of moisture, you can also use full waste paper. Only on the basis of the above standard, add certain wet strength agent 0.5~1.0% and the wet strength can reach 10~15% of dry strength.

- For meat or other wet goods, the same can be used all waste paper manufacturing shopping bags. This needs to be added to the pulp in the process of papermaking or surface coated with environmentally friendly anti-oil agent. Can also be used on the surface strength of good cowhide boxboard paper on the second spraying water-soluble or degradation-type resin.

- Many manufacturers in mainland China, has developed a full waste paper clip tendon paper. That is, when copying paper, two layers of pulp combined with textile principles added into the water-soluble yarn, the paper layer can reach the strength of four layers of kraft paper, can completely replace the ordinary cement bag paper. Similarly, single-ply paper can be used for shopping bags.

- These products are safe and environmentally friendly.

Advertising Type Shopping Bags

knowledge-Based Shopping Bags

Gift-Type Shopping Bags

Commemorative Shopping Bags

Simple Shopping Bags

Trendy Shopping Bags

Environmentally Friendly Shopping Bags

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.