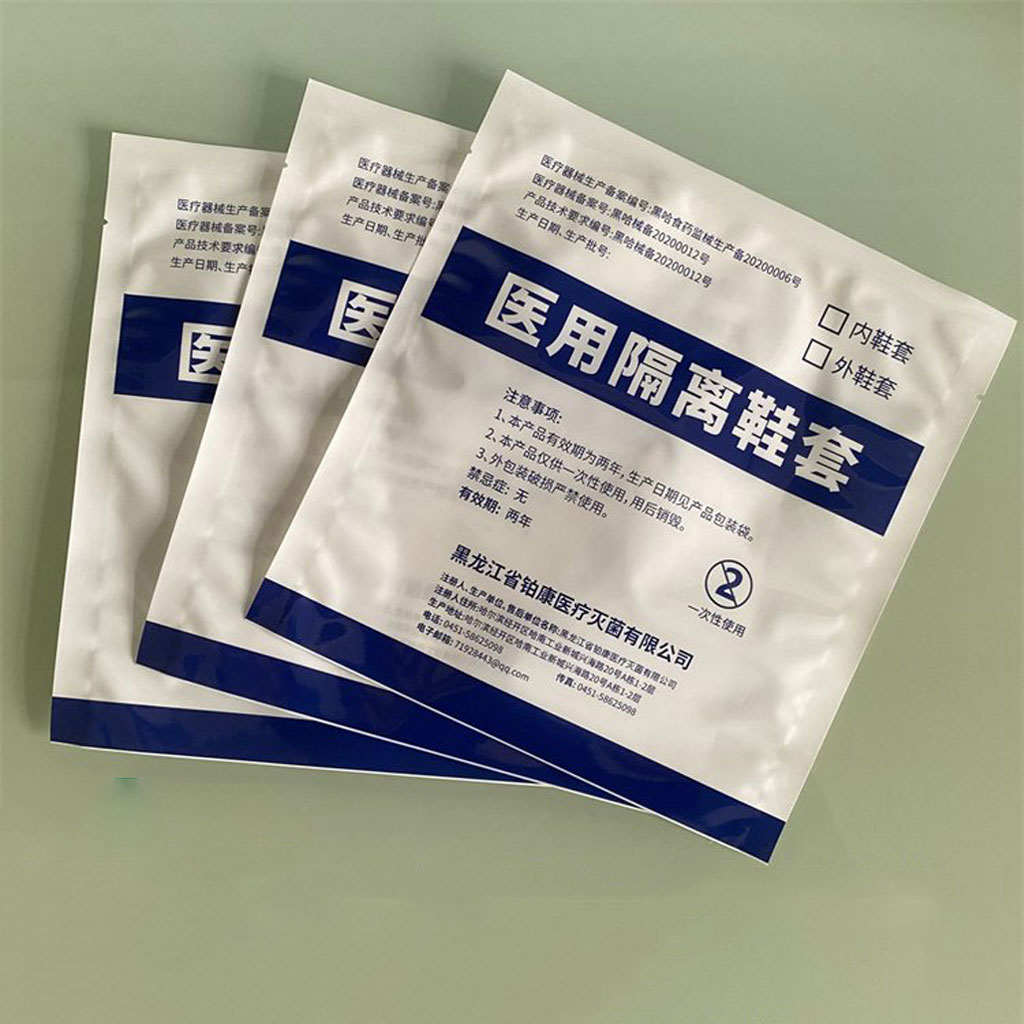

Shoe Cover Packaging Bags

- Surface Handling:Gravure printing

- Industrial Use:Medical

- Material Structure:Composite Material

- Bag Type:FLAT BAG

- Sealing & Handle:Zipper Top

- Custom Order:Accept

- color:clear/customized color

- Size:Custom

- Logo:Customer’s Logo

- MOQ:500pcs

- Thickness:25-100Micron

High-Quality Custom Self Sealing Bag For Medical Shoe Cover

The definition of medical device sterilization packaging should be understood as: packaging for medical device products that can be sterilized, can be operated aseptically (such as clean open), can provide acceptable microbial barrier properties, can protect the product before and after sterilization and can maintain a sterile environment inside the system for a certain period of time after sterilization (marked expiration date).

Products also known as: medical self-sealing bags, sterilization self-sealing bags, sterilization bags, sterilization packaging bags, sterilization flat bags, medical packaging bags, sterilization packaging bags, medical packaging bags, medical composite bags, paper-plastic sterilization bags, medical sterilization bags, medical sterilization bags, sterilization packaging bags, medical sterilization packaging bags, medical dialysis bags, paper-plastic bags, medical paper, etc.

Applications: hospitals, outpatient clinics; beauty supplies; laboratory supplies; medical gloves, gauze, cotton balls, masks, medical catheters, tracheal intubation, surgical gowns, protective clothing, intravascular catheters, indwelling needles, electric knife pens, heparin caps, tee rotors, howler masks, balloons, artificial joints, surgical equipment, dental equipment, medical syringes and other medical supplies packaging and high-end medical equipment packaging.

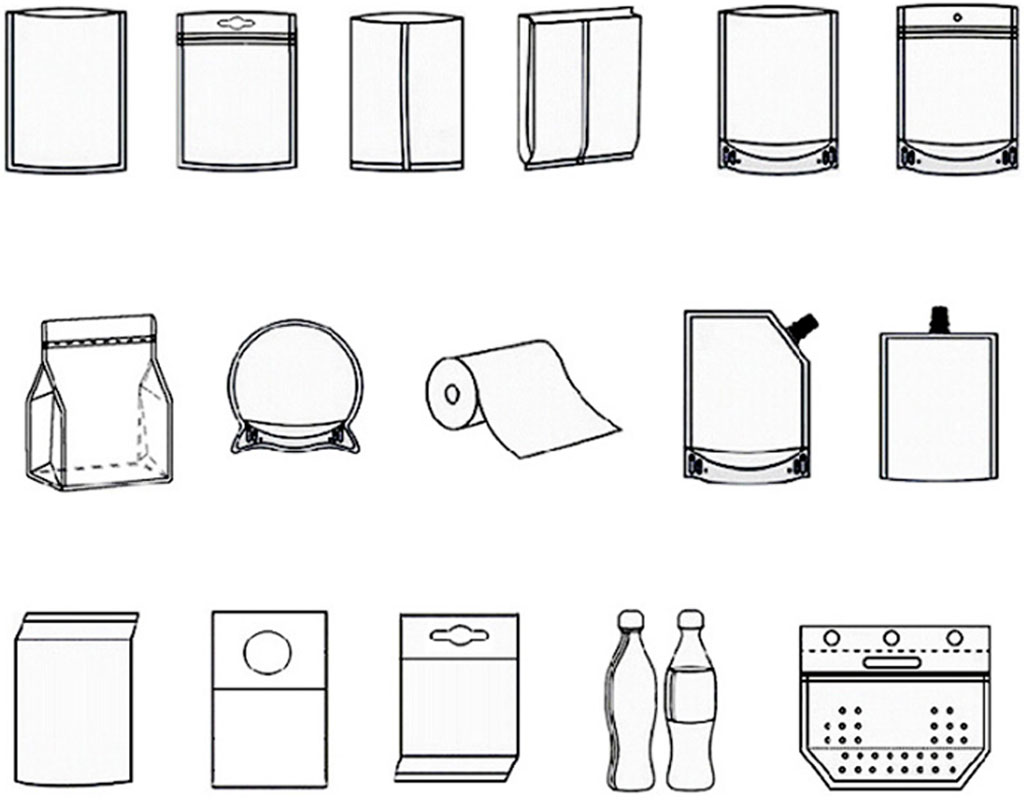

THE MATERIAL LIST FOR CUSTOM PACKAGING BAG

There are so many types of poly and plastic bags out there, it may make your head spin. From gusseted bags to lay flat poly bags, anti-static poly bags to postal approved mailer bags... here's a quick reference guide on the types of plastic bags, which are most commonly referred to as poly bags in the world of packaging.

THE BAG TYPE FOR CUSTOM PACKAGING BAG

THE BAG COLORS FOR CUSTOM PACKAGING BAG

Plastic bags and films generally come in twelve printing colors such as red, yellow, orange, green pink, clear, gray, blue and more. However, Wonder Plastic manufactures them in any color you prefer! Our custom manufacturing makes it simple and easy to get exactly what you need.

OUR CAPABILITIES & PROCESS FOR CUSTOM BAG & FILMS

Wonder Plastic Inc is your single source for all of your plastic bag needs. Family-owned for over 20 years, we've been known for our outstanding customer service.Our highly skilled team works alongside our customers through all steps of the process to ensure that our products fit their specifications. At Wonder Plastic,we specialize in top-quality and hard-to-find packaging, shipping, and workplace products. You name it - bags, boxes, tape, bubble, stretch wrap, safety supplies, office supplies, medical, and lockout and tagout products…WE offers a wide selection of a variety of plastic bag styles and customization to ensure all of your needs are met.

- Ultimate packaging solutions for your custom-engineered and consumer-friendly Mylar Bags with a wide array of finishing options and laminated structures.

- 24/7 after-sales service to stand by you.

- Constant quality audits to safeguard consistent and reliable product quality.

- Committed to Quality, ISO9001 Certified.

- Economical Solutions, Flexible to Suit Your Industries.

- Food-Grade Material, FDA & BRC Approved.

Step 1: Learn about requirements

Step 2: Discuss about requirements

Step 3: Attractive design

Step 4: Start Bag Making

● We have multiple production lines that can make bags of various styles

● We can make bags with unique functions according to your needs

● We have a strong production capacity, with a daily production capacity of more than one million bags

● We produce many kinds of bags, including zipper bags, frosted bags, spout bags, self-supporting bags, etc.

Step 5: Copper Plate Printing

● Printing width range up to 65 inches

● The machine has a built-in quality monitoring module to detect whether the product quality is qualified automatically

● Can meet the requirements of multi-layer composite printing

● The excellent printing technology makes the printing result more precise and can be applied to smaller patterns

● Allows you to production costs and reduces the lead time without frequent changing of the cylinders

● Can be applied to all packaging material surfaces

● Food-grade and environmentally-friendly inks ensure that the product can be used safely

Step 6: Adhesive Laminating Process

● Called solvent-free laminating, the dry bond laminating has no liquid components.Because there is no chemical substance involved, it is safe for us and will not release harmful substances under complicated conditions such as high temperature. So, it is widely used in the food packaging industry, especially high-temperature food packaging.

Step 7: Roll Slitting

● Super high precision slitting width from 3 mm to 1500 mm

● Ability of our roll slitting machine is to rewind roll within 50 cm

● Dimension deviation controls within 1 mm

● Maximum slitting speed is 300 m/min

Step 8: Quality Inspection

● Passed international related product certification

● Through the laboratory, the product quality is inspected and monitored in all aspects of production

OUR IN-HOUSE MACHINE FOR CUSTOM PACKAGING BAG

Order Your Plastic Bags Or Films from Wonder Plastic Now

We are also well-known for customization and can assist you in printing your Plastic Bags or films manufacturers as we are experts at customizing a packaging bag to suit your requirements. All you need to do is select the size and length of bag that suits your requirements, and we can help you with the logo and graphics. We have amazing wholesale Plastic Bags Or Films offers. We offer attractive prices on bulk orders. So, place your oeder really fast.