PO FOR PACKAGING BAG

PO, high-density polyethylene is also called HDPE, high-pressure plastic bags.This kind of bags are more brittle, harder, low stretch rate.

Sound brittle when kneading, due to better tensile strength, widely used in shopping malls, hotel industry.

Opaque, brittle, non-toxic and tasteless, has excellent low temperature resistance (the minimum operating temperature can reach -70 ~ -100 ℃), good chemical stability, can resist the erosion of most acids and bases (not resistant to acids with oxidizing properties), insoluble in general solvents at room temperature, small water absorption, excellent electrical insulation properties, is one of the most commonly used plastic bag packaging materials.

Commonly used PO plastic bags are mainly three, which is most commonly used than our usual use of undershirt bags, now almost all the undershirt bags on the market are made using PO materials, in addition to industrial production with flat pockets and along the line of bags (R bags) many are also made using PO materials.

PO material made of bags with a low gloss (the surface looks more foggy, the thicker it looks the more foggy, sometimes even close to white) slightly hard texture, lightly shaken by hand, you can hear the clattering sound.

SPECIAL CHARACTERISTICS OF PO BAGS

PO plastic bags it can be very thin and thin, according to our current mastery of technology, 1 silk can be produced, while PE and PP thickness can only do 2 silk, PP can not even, so the PO price advantage is more obvious. However, PO plastic bags are nearly white, the use of relatively much smaller.

APPLICATION OF PO BAGS

PO plastic bags are commonly used as a kind of food packaging plastic bags, the film is non-toxic, so it can be used to hold food. There is also a film made of polyvinyl chloride, polyvinyl chloride itself is not toxic, but according to the use of film added additives are often harmful to humans, with a certain degree of toxicity. So this type of film and plastic bags made of the film are not suitable for food.

OUR CASE STUDIES OF PO PACKAGING BAG

Currently, our custom packaging bags are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom packaging bag fabrication service provides durable and affordable plastic bag that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, Supermarkets, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your custom packaging bag project.

-

PE Biodegradable Material PET Poop Bags

-

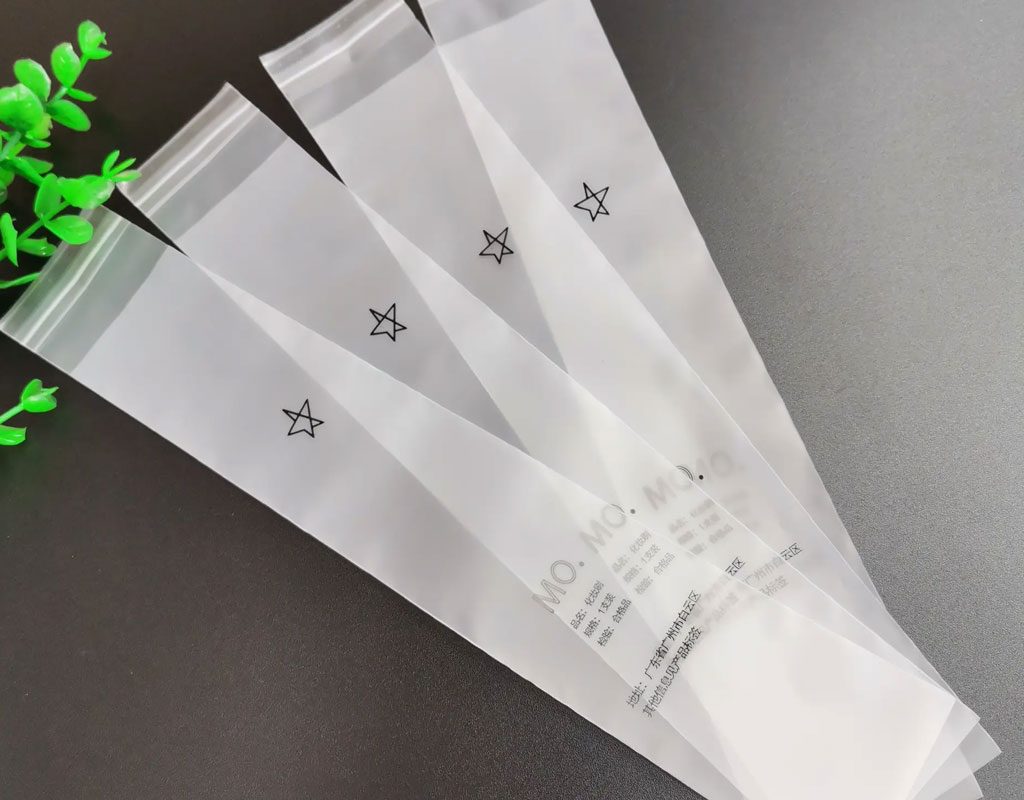

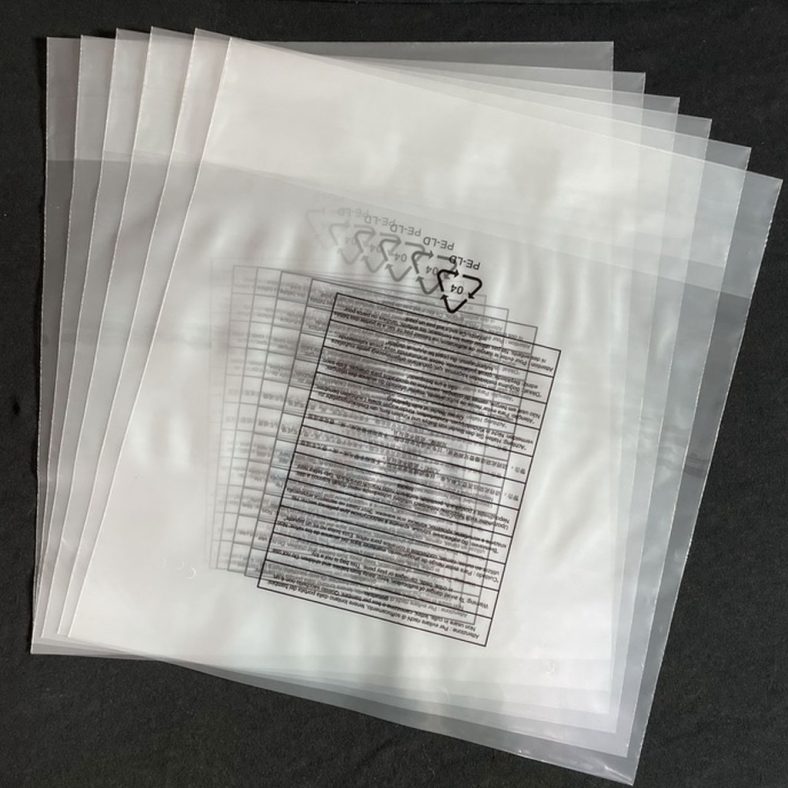

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

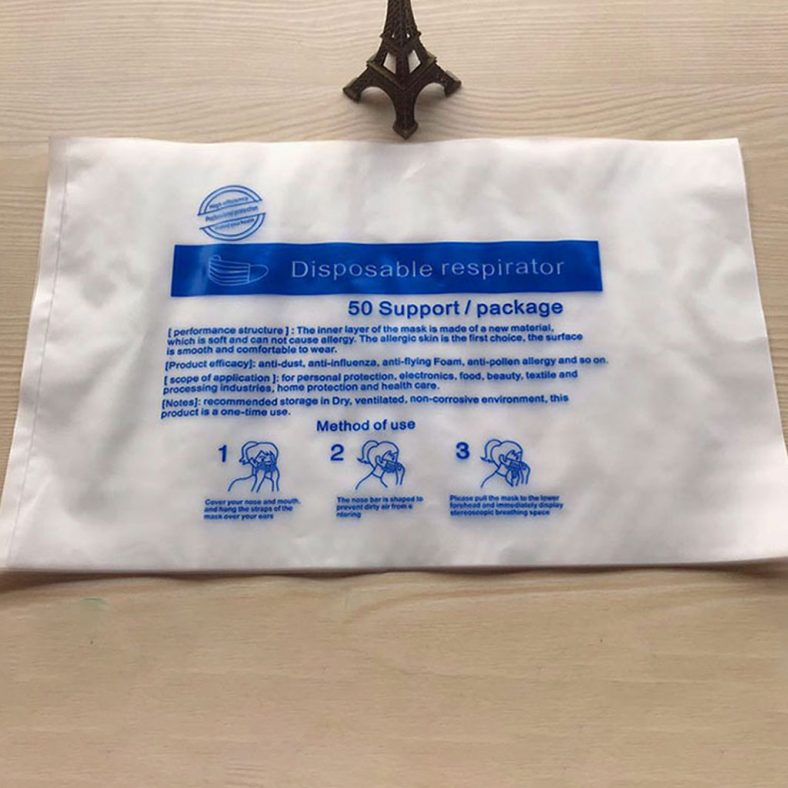

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

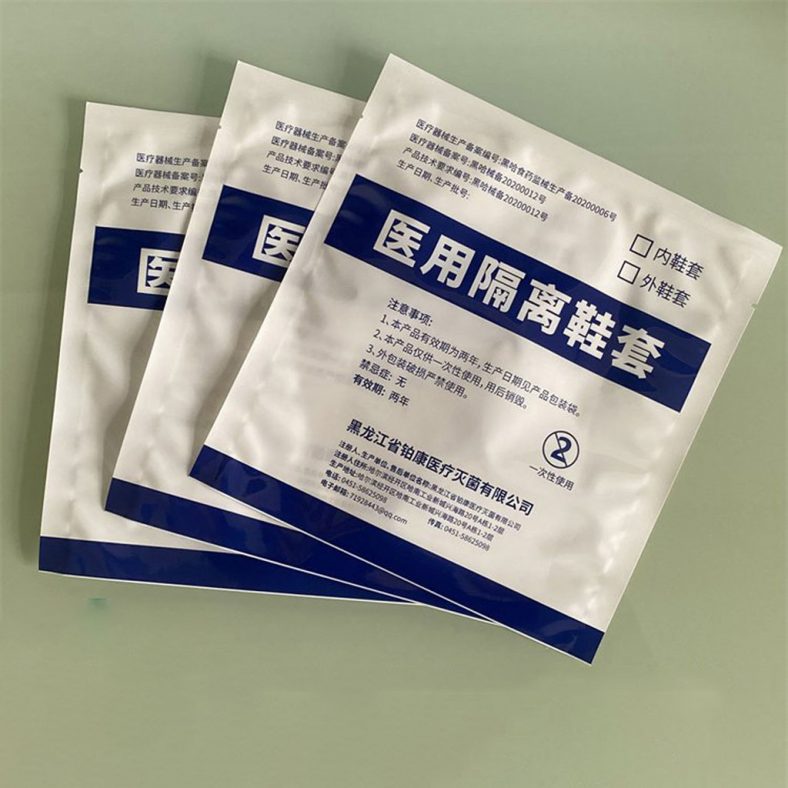

Self Sealing Bag For Medical Shoe Cover