PVA Film Manufacturer

PVA coated high barrier film is added to the nano inorganic PVA coated in polyethylene film after printing, lamination, without significantly increasing the cost of the premise, its barrier performance is not only significantly better than the EVOH five-layer co-extruded film, and packaging costs are also significantly reduced, which can not only ensure that the packaged goods for aseptic packaging all the quality requirements, but also significantly reduce the cost of aseptic packaging for food processing enterprises, can be used to package beverages, fruit juice, milk, soy sauce vinegar, etc.

Wonder Plastic is a custom supplier of pva film and tubing. No matter what you’re looking for, we can accommodate nearly any specifications to deliver the plastic film or tubing that best suits your application.

-

PE Biodegradable Material PET Poop Bags

-

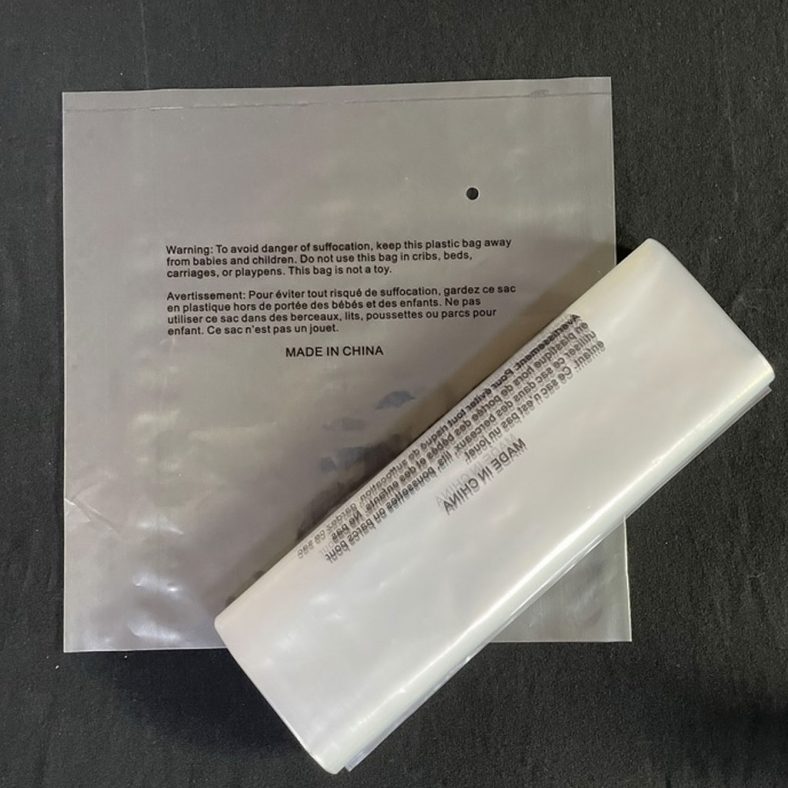

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

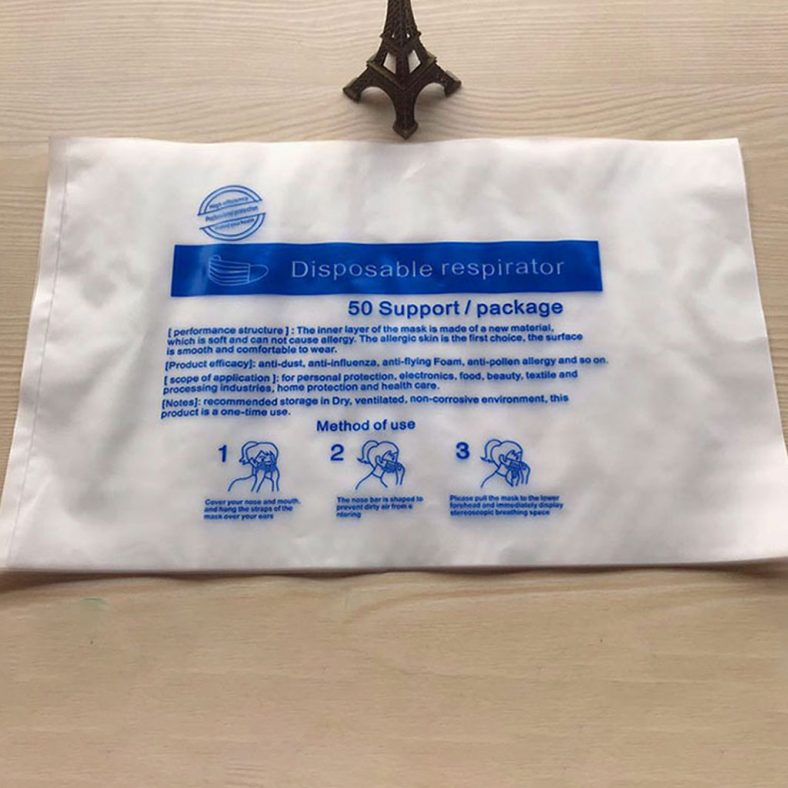

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

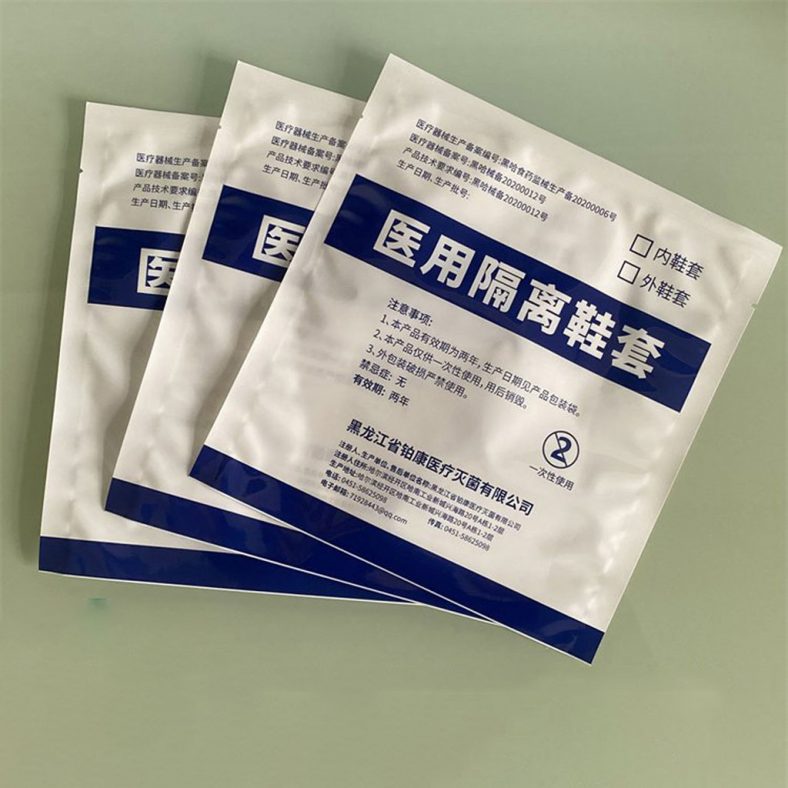

Self Sealing Bag For Medical Shoe Cover

PVA coated high barrier film is a multilayer structured film made by laminating gas barrier material with polyolefin which has a high thermal seam and moisture barrier.

The PVA coated high barrier film is processed through a lamination process, and the printed text and patterns are all wrapped in the middle layer of the film, which effectively prevents ink loss and reduces ink pollution. The nano material in the barrier layer has a good shielding effect on infrared and ultraviolet rays and will not cause any adverse effects on the quality of the packaged film such as dairy products, nor will it cause odour to the packaged film. More importantly, the high barrier composite film has a very good barrier effect on O2, CO2 and various aromas, preventing secondary contamination of the packaged film by atmospheric micro-organisms and preventing the replacement of gases with air required for the reproduction of micro-organisms in the packaged film foodstuffs. It can effectively prevent the oxidation and deterioration of dairy products and other packaged foodstuffs.

- Cost Effective:The production cost of PVA laminate films is much lower than the production cost of packaging materials with paper-aluminium-plastic laminate and aluminium-plastic laminate structures, and lower than the cost of PVDC-coated laminate films.

- Excellent Oxygen Barrier Properties:Modified polyvinyl alcohol (PVA) laminate films have good barrier properties to oxygen, nitrogen, hydrogen and carbon dioxide, and their oxygen barrier properties are much better than those of PVDC laminate films.

- Excellent Fragrance Retention:It can maintain the original flavour of the food inside the bag for a longer period of time, while at the same time effectively blocking odours from outside the packaging material from entering the bag.

- Excellent Environmental Protection Material:The structural composition of PVA coating liquid is carbon, oxygen, hydrogen and silicon, which is degradable, recyclable and reusable, does not produce toxic gases after burning, no pollution and is an ideal packaging material.

PVA coated packaging film and PVDC coated packaging film, are currently more widely used in industrial production of coated barrier packaging film. Both coated packaging films have a lot in common, but also have many completely different places. Understanding their similarities and differences, for our rational development, the application of coated barrier packaging materials, is very necessary.

1.The Commonalities Of PVA Films And PVDC Coated Packaging Films

PVA coated packaging film and PVDC coated packaging film is the same, mainly in the following points: first, the oxygen have excellent barrier properties; second, can be made into transparent film, can meet the needs of high transparency packaging materials for commodities; third, can be through the microwave, and thus the food packaged can be heated in a microwave oven; fourth, they are applied to enhance the film coating Fourthly, they both apply coatings to enhance the barrier properties of the film, so the raw material consumption is low.Despite these similarities, the two films belong to two different categories, with many distinctive differences and unique characteristics.

2.The Advantages Of PVDC Coated Film

PVDC coated film also has excellent oxygen barrier and water vapour barrier performance, and can be compounded with other films and then used, can also be used directly after the coating, such as cigarette packaging with PVDC coated film. In contrast, PVA coated films only show excellent barrier properties to oxygen, the barrier properties to water vapour are insufficient, and in high humidity conditions, the PVA coating will also absorb water and lead to a significant reduction in oxygen barrier properties, so in PVA coated films, moisture resistant plastic films need to be used to protect the PVA coating to ensure high oxygen barrier properties of the film. In addition, as the current PVA coated film is not yet heat-sealable, it is also required to be laminated with a moisture-resistant polyolefin film before it is put into practical use.

3.The Advantages Of PVA Coated Film

PVA coated packaging film compared to PVDC coated packaging film advantages, first of all, in the PVA coated packaging film better adaptability to environmental protection. PVA although thermal stability is not good, can not use ordinary thermoplastic equipment and conventional thermoplastic molding process for film production, but coated with PVA coated polyolefin film, can still be used to melt regeneration granulation method to be recycled, and because there are no chlorine atoms in the PVA molecule, when burning films containing PVA coating, only carbon dioxide and water, will not produce hydrogen chloride, dioxins and other toxic and harmful substances. On the contrary, PVDC, its thermal stability is very poor, there is no melt recycling technology in the world to deal with packaging waste containing PVDC, and as a result of PVDC molecules, containing more chlorine atoms, when the packaging waste containing PVDC for combustion treatment, will produce hydrogen chloride, dioxins and other toxic and harmful substances, so PVDC there is the problem of environmental protection adaptability, has become People are highly concerned and research one of the key issues, but also the development and application of PVDC-type packaging materials, a major bottleneck. I believe that, from the point of view of sustainable development, in the PVDC environmental protection adaptability problems have not made a breakthrough before, should try to advocate the use of PVA type barrier packaging materials.

In addition to environmental protection adaptability, PVA coated barrier packaging materials compared to PVDC coated barrier packaging materials of other advantages include: the use of modified PVA coating solution for coating, because the modified PVA and the base film has a good adhesion between the production process can be constructed without primer, and the use of PVDC coating, in order to make PVDC coating and base film between a large enough Adhesion to ensure the use of the needs of the base film must be primer construction, thus lengthening the process route, production costs rise; PVA on the oxygen barrier than PVDC high, the coating amount of 0.3 ~ 0.4g/m2, that can reach 5cm3/m224h0.1MPa or so of oxygen permeability, and when coated with PVDC, to reach 5cm3/m224h0.1 MPa or so of oxygen permeability, the need for 3g/m2 or so of coating volume, so the use of PVA coating, not only can save coating liquid, but also easier to achieve high-speed coating; using modified PVA coating liquid, construction is convenient, both the use of special coating machine for coating, but also the use of ordinary gravure or dry laminating equipment for high-speed coating, which is very beneficial to the promotion and application of PVA coating.

Based on the above advantages of PVA coated barrier packaging materials, we have every reason to expect that PVA coated barrier packaging materials, in the future a not too long time will gain greater development.

After the polyvinyl alcohol has been modified, the water resistance of the coating is significantly improved, but compared to polyolefin plastics, modified polyvinyl alcohol is still susceptible to water vapour, i.e. in a humid environment, the barrier properties of the modified polyvinyl alcohol coating will still show a tendency to decrease in barrier properties as the ambient humidity increases. Therefore, the end product of the composite film containing PVA coating, usually on both sides of the coating, are excellent moisture barrier polyolefin film, so that the PVA coating is not affected by environmental humidity and always in a dry state, thus giving the composite film for oxygen and other non-polar gases good barrier, so that it also shows high oxygen barrier, moisture barrier performance. Here are a few examples of coated PVA barrier packaging films, combined with specific examples.

- General purpose barrier films for food packaging

- Laminated film for milk packaging

- Steam-resistant BOPP/AD/modified PVA coated/IPP laminate film

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.