PET Film Manufacturer

Polyester film (PET) is a film material made from polyethylene terephthalate, which is extruded into thick sheets and then stretched. Polyester film Eco-friendly film PET film Opalescent film and other printing and packaging consumables, widely used in the glass and steel industry, building materials industry, printing industry, medicine and health. Polyester film is also called polyester film Optical film Polyester film Sensitive paper Polyester film Benzene tin film Cellophane Release film.

Wonder Plastic is a custom supplier of PET film and tubing. No matter what you’re looking for, we can accommodate nearly any specifications to deliver the plastic film or tubing that best suits your application.

-

PE Biodegradable Material PET Poop Bags

-

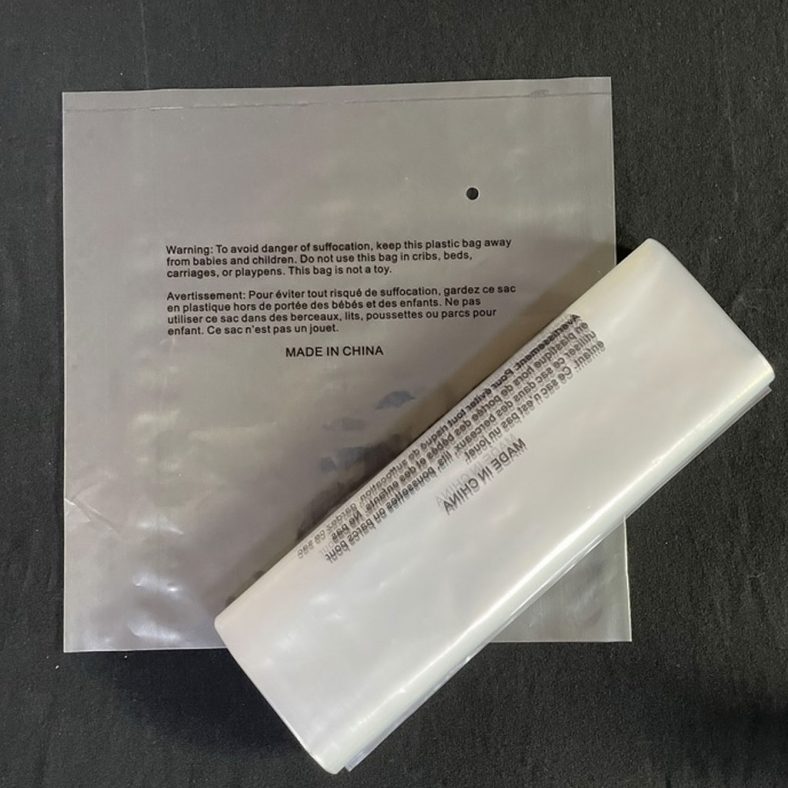

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

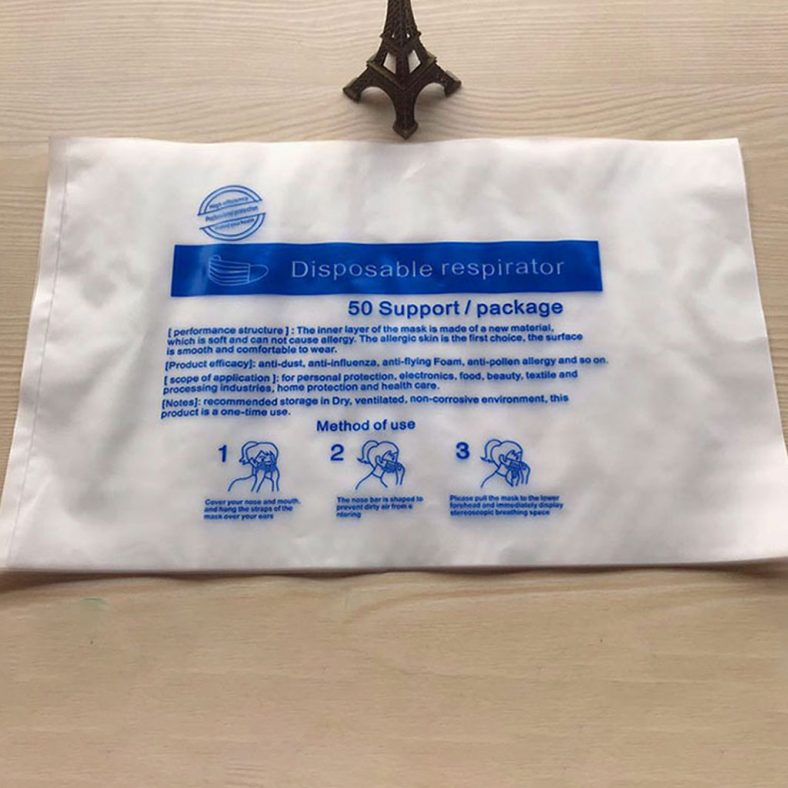

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

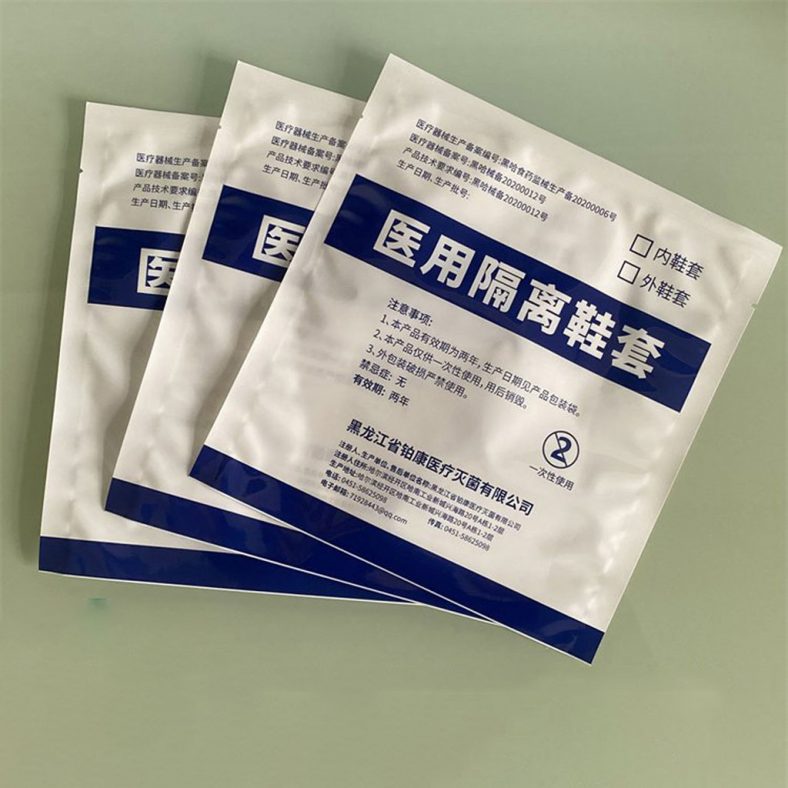

Self Sealing Bag For Medical Shoe Cover

Polyester film is a kind of polymer plastic film, which is increasingly favoured by the majority of consumers because of its excellent overall performance. As China’s production volume and technical level still cannot meet the market demand, part of it still needs to rely on imports. It is usually a colourless, transparent and glossy film (it can now be coloured by adding additive particles) with excellent mechanical properties, high rigidity, hardness and toughness, puncture resistance, friction resistance, high and low temperature resistance, good chemical resistance, oil resistance, air tightness and fragrance retention, and is one of the commonly used substrates for permeability compound films, but has poor corona resistance.

- Biaxially oriented polyester film (referred to as BOPET), is the use of light material (also known as large light material, that is, in the raw material polyester slice titanium dioxide content of 0.1%, after drying, melting, extrusion, casting and longitudinal stretching of high-grade film, a wide range of uses). toughness; its tensile strength is PC film, nylon film 3 times, impact strength is BOPP film 3-5 times, has excellent abrasion resistance, folding resistance, pinhole resistance and tear resistance; heat shrinkage is very small, at 120 ℃, only 1.25% shrinkage after 15 minutes; has good antistatic properties, easy to vacuum aluminizing, can be coated with PVDC, so as to improve its heat sealing, barrier and Printing adhesion; BOPET also has good heat resistance, excellent resistance to cooking, low temperature freezing resistance, good oil resistance and chemical resistance, etc. BOPET film cannot be dissolved by most chemicals except for nitrobenzene, chloroform and benzyl alcohol. However, BOPET will be subject to the erosion of strong alkali, the use of attention should be paid to the BOPET film low water absorption rate, good water resistance, suitable for packaging high water content of food.

- One-way stretch polyester film (referred to as CPET), is the use of semi-opaque material (raw material polyester slices with titanium dioxide), after drying, melting, extrusion, casting and longitudinal stretching of the film, the lowest grade and price in the polyester film, mainly used for pharmaceutical tablet packaging. Due to the use of less, manufacturers less large-scale production, about 5% of the field of polyester film, China’s enterprises are also less imported, the standard thickness of 150μm.

The properties of polyester films determine their different uses. Different uses of polyester films have different requirements for raw materials and additives as well as processing techniques, and their thickness and technical indicators are different; in addition, only BOPET has a variety of uses, so the films classified according to their uses are all BOPET. can be divided into the following categories.

Electrical Insulation Film

Capacitive Film

Card Guard Film

General Purpose Film

With excellent strength and dimensional stability, cold resistance and chemical stability, it is widely used in various substrates such as laminated packaging, photographic film, metal vapour plating, audio and video recording. Specifically, there are the following types.

- Semi-Reinforced Films. The main feature is the longitudinal tensile strength, not easy to break under greater tension, mainly used for boxed items such as packaging seals. Commonly used standard thicknesses are 20μm, 28μm, 30μm, 36μm, 50μm.

- Stamping Film. The most important features are good tensile strength and transparency, stable thermal properties and low bonding with certain resins. It is mainly suitable for applications where there is little dimensional change during high temperature processing or as a transfer carrier. Conventional standard thicknesses are 9μm, 12μm, 15μm, 19μm, 25μm and 36μm.

- Printed Laminated Packaging Films. The main features are good transparency, good resistance to penetration, superior chemical resistance, temperature resistance and moisture resistance. It is suitable for frozen food and packaging of food, pharmaceuticals, industrial products and cosmetics. Commonly used standard thicknesses are 12μm, 15μm, 23μm and 36μm.

- Aluminium-Plated Film. The main characteristics are high strength, good temperature and chemical resistance, good processing and anti-ageing properties, and proper corona treatment, which makes the adhesion of aluminium layer and film more solid. After being used for aluminizing, it can be widely used for packaging of tea, milk powder, candy, biscuits, etc. It can also be used as a decorative film such as string flower crafts and Christmas trees; it is also suitable for printing lamination or cardboard lamination. The conventional standard thicknesses are 12μm, 16μm, 25μm and 36μm.

- Magnetic Recording Film. It has good dimensional stability, uniform thickness and high tensile strength. Suitable for magnetic recording material base film and special packaging film. Including audio and video tape base (common standard thicknesses are 9-12μm) and black film (common standard thicknesses are 35-36μm).

Nano PET Film

Different manufacturers can have different classification names according to the quality of polyester film, and manufacturers in China are generally divided into superior products, first-class products and qualified products, while foreign manufacturers are generally divided into A-grade products, B-grade products and C-grade products. In general, 97-98% of the products sold by manufacturers are A-grade products, while B-grade products account for only 2-3% and C-grade products are unqualified products that are not sold in circulation. The main reason is the high price of raw materials, the general manufacturers will be back to the furnace as raw materials, or will be sold to textile mills as staple fibres for textile raw materials. Foreign manufacturers sometimes also sell their quarterly or half-yearly stocks of film as B-grade products, a consistent practice of some manufacturers in Southeast Asian countries, with the aim of reducing stocks.

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.