LDPE Film Manufacturers

LDPE films are generally made using both blow moulding and cast processes. Cast polyethylene film is of uniform thickness but is rarely used due to its high price. Blown polyethylene film is made from blow moulded grade PE pellets blown by a blow moulding machine and is the most widely used as it is less expensive. LDPE film is a translucent, glossy, softer film with excellent chemical stability, heat sealability, water and moisture resistance, freeze resistance and can be boiled in water.Manufacturer of standard and custom stretch, shrink, bundling, multilayer, Surlyn® and skin packaging film. Made from LDPE Film. Capabilities include bag filling, labeling and contract packaging. Secondary services such as supply chain management, repair, rebuild and preventative maintenance provided. Prototype and low to high volume production runs available

-

PE Biodegradable Material PET Poop Bags

-

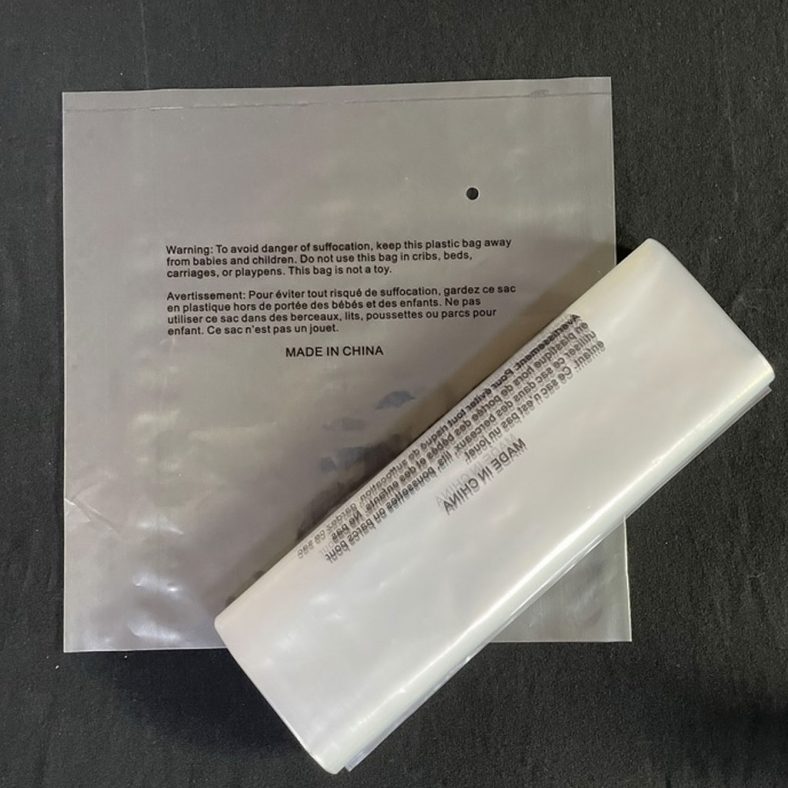

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

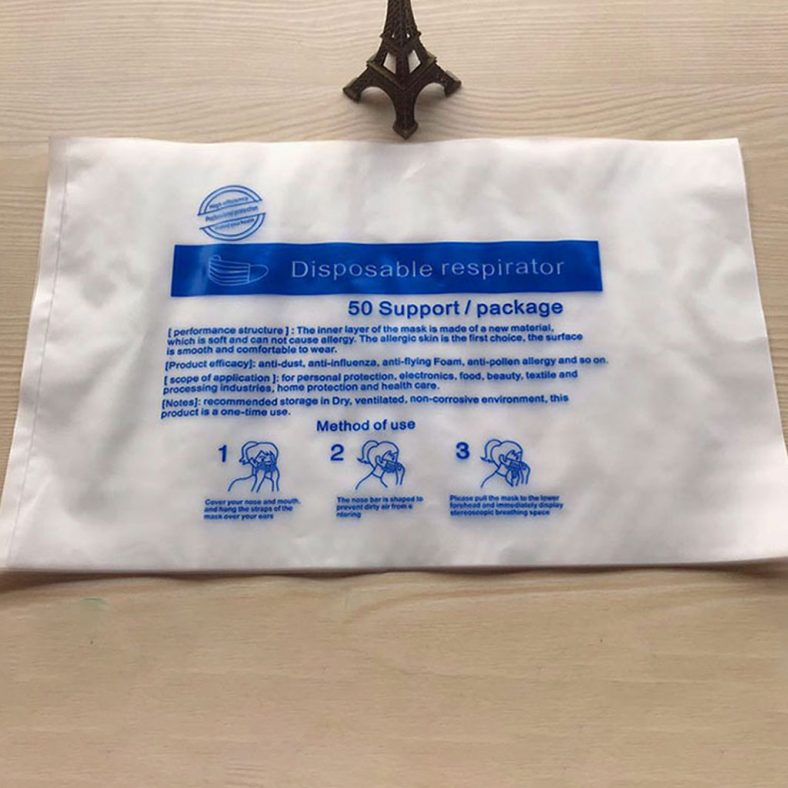

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

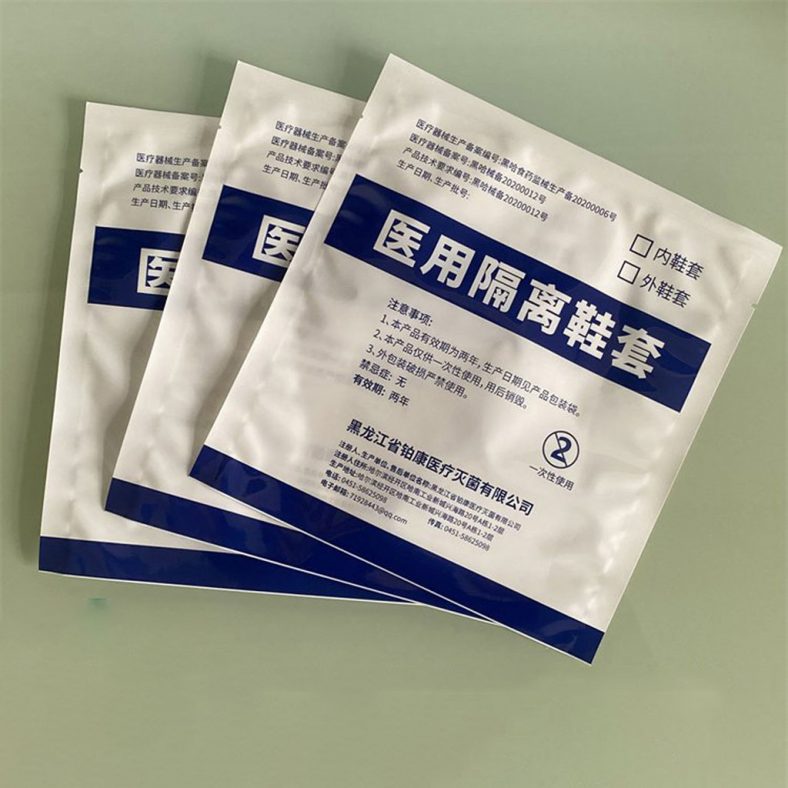

Self Sealing Bag For Medical Shoe Cover

(LDPE), whose main drawback is its poor barrier to oxygen, is commonly used as the inner film of composite flexible packaging materials and is also one of the most widely used and largest plastic packaging films, accounting for about 40% or more of plastic packaging film consumption.

As polyethylene molecules do not contain polar groups, and high crystallinity, the surface free energy is low, therefore, the film has poor printing performance, poor adhesion to ink and adhesive, so the surface treatment is required before printing and lamination.

- The film is slightly opalescent and transparent and soft. The strength is smaller than that of HDPE, while the impact strength is greater than that of HDPE.

- Cold, low temperature and higher temperature resistance. Thicker films can withstand the sterilisation process by immersion in hot water at 90°C.

- Moisture resistance is better, chemically stable and insoluble in general solvents.

- There is a large air permeability, so when used as oxidation-prone food packaging, the storage period of its contents should not be too long.

- Poor grease resistance, products can be slowly dissolved up. Packaging containing grease food, long storage will make the food appear harsh taste.

- A long period of ultraviolet light and heat will be aging, affecting its physical properties and dielectric properties.

- Melting point of 110 ~ 115 ℃, processing temperature of 150 ~ 210 ℃, if inert gas, the temperature can reach 300 ℃ is still stable. However, the melt is susceptible to degradation when in contact with oxygen.

Application range of LDPE: Suitable for food packaging such as seasoning, pastry, sugar, preserves, biscuits, milk powder, tea, fish and meat pine. Packaging for pharmaceuticals such as tablets and powders, shirts, garments, knitted cotton products and chemical fibre products and other fibre products. Packaging for daily chemical products such as laundry detergent, detergent and cosmetics. Due to the poor mechanical properties of single-layer PE film, it is usually used as the inner layer of composite packaging bags, i.e. multi-layer composite film heat sealing substrate.

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.