CPP Film Manufacturers

Cast polypropylene film is a polypropylene film produced by the flow casting process, and can be divided into two kinds of ordinary CPP and steaming grade CPP, excellent transparency, uniform thickness, and uniform performance in the longitudinal and horizontal directions, generally used as the inner layer of the composite film material. The thickness of ordinary CPP film is generally between 25 and 50 μm, with OPP lamination, good transparency, bright surface and a firm feel, generally used for gift bags. This film also has good heat sealability. The thickness of CPP film is generally between 60 and 80 μm, which can withstand 121°C, 30 min of high temperature cooking, oil resistance, air tightness, and high heat sealing strength, and the general meat packaging inner layer are used to steam grade CPP film.

Manufacturer of surface protective CPP Films. Offered in 300 ft., 600 ft. and 1000 ft. lengths and widths up to 72 in. Custom widths and lengths also available. Perforating and die cutting services are available. Markets served include architectural, commercial, construction, electronics and furniture.

-

PE Biodegradable Material PET Poop Bags

-

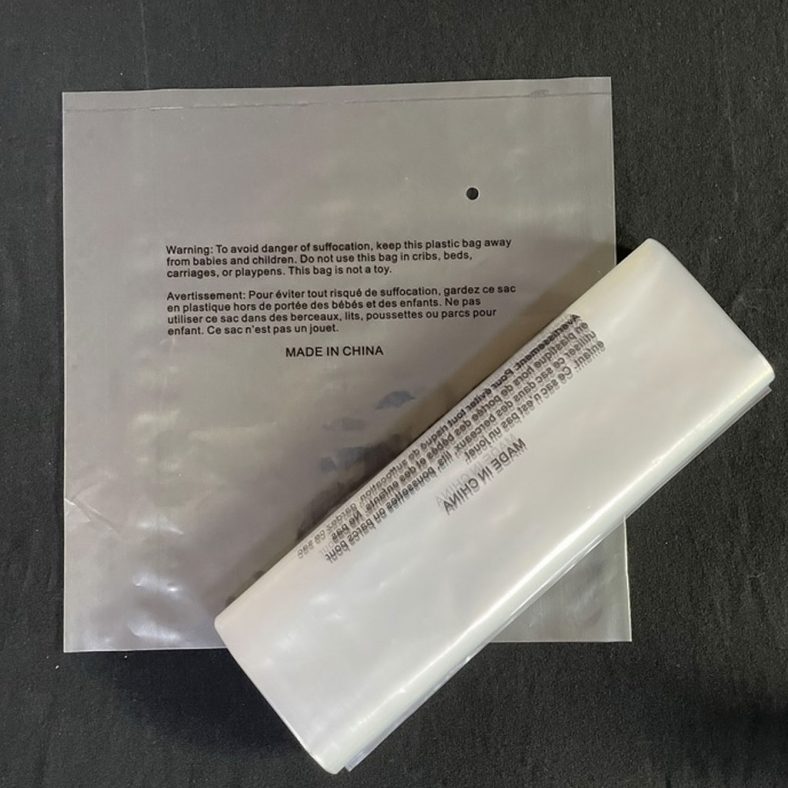

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

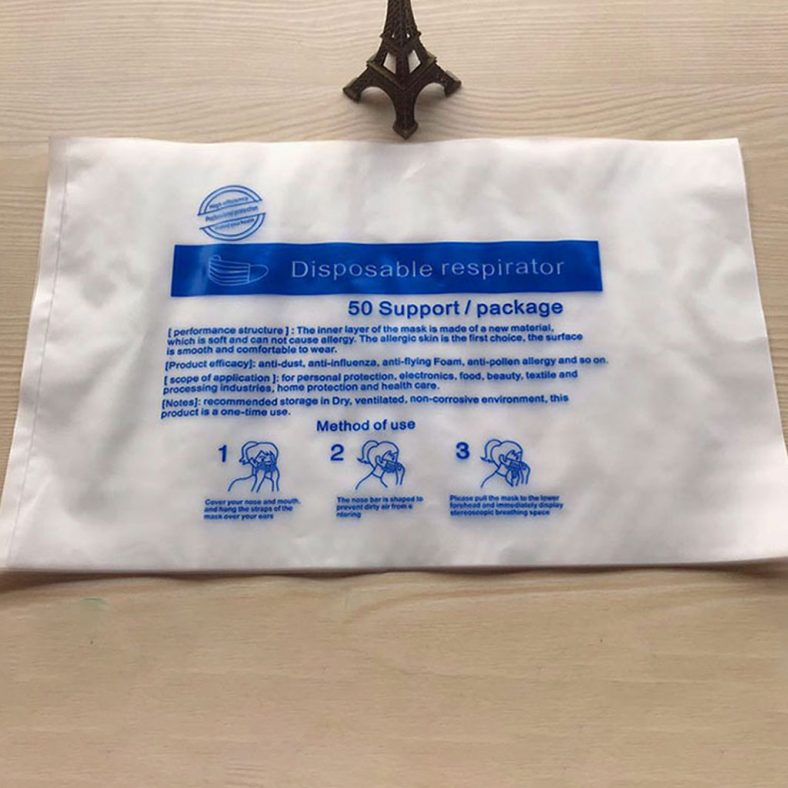

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

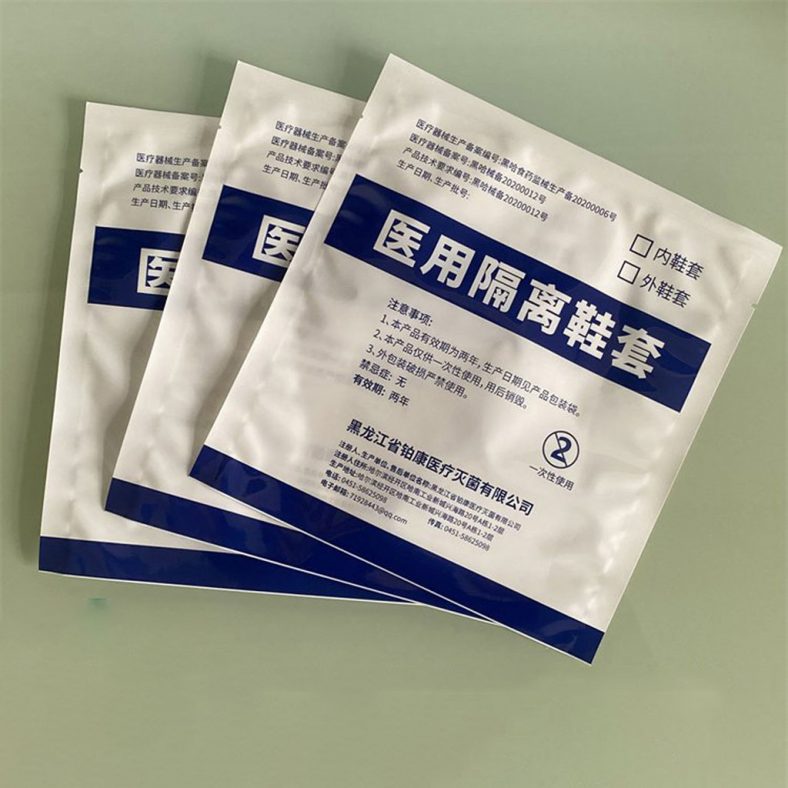

Self Sealing Bag For Medical Shoe Cover

It can be divided into General CPP (General CPP, or GCPP) film, Metalize CPP (Metalize CPP, or MCPP) film and Retort CPP (Retort CPP, or RCPP) film, which has excellent transparency, uniform thickness and uniform performance in the longitudinal and transverse directions, and is generally used as the inner layer of composite films. The thickness of ordinary CPP film is generally between 25 and 50 μm, with OPP lamination, good transparency, bright surface and a firm feel, which is generally used for gift bags. This film also has good heat sealability. The thickness of CPP film is generally between 60 and 80 μm, which can withstand 121°C, 30 min of high temperature cooking, oil resistance, air tightness, and high heat sealing strength, and the general meat packaging inner layer are used to steam grade CPP film.

According to industry insiders, in the world packaging materials market, the production of cast film is continuing to rise, cast film industry is entering a new round of investment boom. China’s cast film production started in the 1980s, and with the continuous development and growth in the past 20 years, the packaging industry has become a sunrise industry with considerable production capacity and production levels.

Polypropylene cast film (CPP) is a non-stretch, non-directional, flat extruded film produced by melt flow quenching. Compared to blown film, it is characterised by fast production speeds, high yields, good film transparency, gloss, thickness uniformity and excellent balance of properties in all directions. Also, as it is a flat extruded film, subsequent processes such as printing and laminating are extremely convenient, making it widely used in the packaging of textiles, flowers, foodstuffs and daily necessities.

CPP is produced in both single-layer cast and multi-layer co-extruded cast. Single-layer films mainly require good low-temperature heat sealing properties and flexibility of the material. Multi-layer co-extruded cast film can generally be divided into three layers: heat seal layer, support layer and corona layer. The choice of materials is wider than that of single-layer film, and materials can be selected individually to meet the requirements of each layer, giving the film different functions and uses. The heat seal layer is required for heat seal processing, which requires a low melting point, good heat melt, wide heat seal temperature and easy sealing; the support layer plays a supporting role for the film and increases the stiffness of the film; the corona layer is required for printing or metallisation, which requires a moderate surface tension and strict restrictions on the addition of additives.

CPP can be used alone for the outer packaging of food, clothing, tissue paper, flowers, etc. after printing and bag making. In addition, due to its excellent transparency, lower heat sealing temperature, can also be used as a base film for a variety of composite films, such as PET film, BOPP film, etc., for packaging fast food products, tea, etc.; and barrier resin EVOH, PA, PVDC, etc., through the adhesive compound, to package food containing grease or soup type. Other applications such as high and medium temperature cooking films, vacuum aluminising films are also important.

With the increasing market demand for cast films, the products and materials used are being updated and new developments in CPP are mainly focused on ultra-low temperature heat sealing films, cold resistant films and high temperature cooking films. Some special films are also being developed, such as anti-static films, pesticide films and highly transparent super-soft films, which are gradually being introduced to the market and are occupying new applications.

The development of CPP production scales and extrusion equipment has led to an increasing use of raw materials and an increasing range of options, which has led to the development of specialised polypropylene materials for cast applications in the direction of greater refinement, specialisation and performance. A variety of specialised materials are emerging with a finer division of labour, each playing its own role at different levels and giving the film new properties to suit different market needs. At the same time, specialised high performance raw materials are being produced for specific user requirements, which will bring greater profitability to resin producers. The hot spot for speciality material development is in low-temperature heat seal materials, with industrially produced butylene/propylene random copolymers being the latest product to be introduced to the market.

Compared with conventional ethylene/propylene random copolymers, this product has a much higher seal strength and less frosting and fogging at the same heat sealing temperature of 100 to 112°C.

In recent years, with the strengthening of the consumer market, the application area of CPP has been expanding and its development has been accelerated. There are more than 30 CPP manufacturers in China, with more than 40 production lines and a total production capacity of 150,000-170,000 tons/year. However, the dependence on imported materials for cast film is more serious than that of BOPP film and blown film.

The annual import volume accounts for about 60% of the total volume used. Domestic CPP special material varieties are relatively single, only Shanghai Petrochemical Company and Beijing Yanshan Petrochemical Company production, generally used for composite film heat sealing layer, semi-boiling film, aluminized film high temperature boiling film with resin, etc. are more lacking. At the same time, domestic enterprises of the same product phenomenon is more serious, the same kind of low and mid-range products of equipment capacity increase than the increase in demand, the market is relatively weak, inhibiting the expansion of film production and price increases. In addition, in the past two years, the multilayer co-extruded blown film market is in the growth phase, some varieties of CPP film by its competition and impact.

CPP has become an indispensable product for the packaging industry, with manufacturers adopting new equipment and materials to continuously expand production, enhance production efficiency, increase product range and expand new application areas. It can be expected that as China’s economy and consumption levels improve, its production development will expand further. At the same time, it should also be seen that the cast film is still partly or fully dependent on imports, how to speed up its localisation is also a major problem that needs to be solved as soon as possible in the plastics processing and resin production industry.

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.