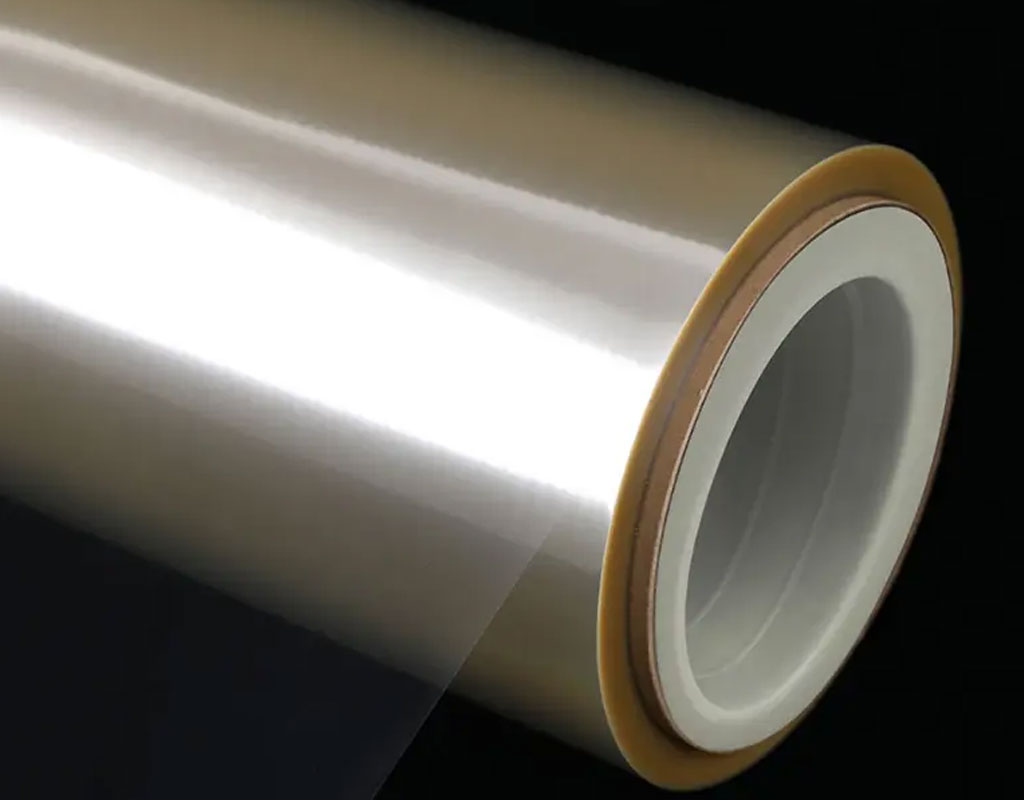

BOPP Film Suppliers

Bi-oriented polypropylene film (BOPP) is generally a multilayer co-extruded film, which is made from polypropylene granules that are co-extruded to form a sheet and then stretched in two directions, longitudinally and horizontally.

Due to the orientation of the stretching molecules, this film has good physical stability, mechanical strength, air tightness, high transparency and gloss, toughness and abrasion resistance, and is widely used as a printing film. The main disadvantage of biaxially oriented polypropylene films is their poor heat sealability, so they are generally used as the outer layer of composite films, such as moisture resistance, transparency, strength, stiffness and printability after lamination with polyethylene films, which are ideal for holding dry food.

As the surface of biaxially oriented polypropylene film is non-polar, with high crystallinity and low surface free energy, its printing properties are poor and its adhesion to inks and adhesives is poor, requiring surface treatment before printing and lamination.Wonder Plastic has been in the BOPP film manufacturing sector for almost 10 years and has a wealth of expertise. This has enabled us to concentrate on perfecting all of our BOPP film manufacturing in order to meet your demands. We collaborate with the top designers in the business to ensure that our creations exceed your expectations. These bottles have fantastic features that make them an excellent purchase to consider. They are built to last and provide the finest performance when in use.

-

PE Biodegradable Material PET Poop Bags

-

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

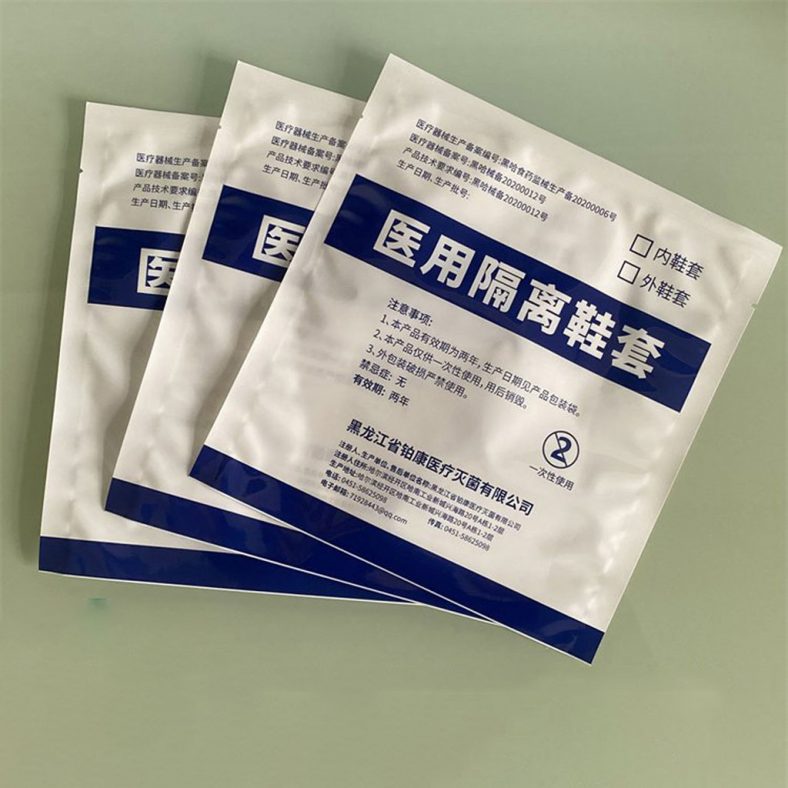

Self Sealing Bag For Medical Shoe Cover

Bi-oriented polypropylene film is light, non-toxic, odourless, moisture resistant, high mechanical strength, good dimensional stability, good printing properties and good transparency. It has the advantages of high transparency, good gloss, good barrier properties, high impact strength and low temperature resistance. The disadvantage is that the film is prone to shrinkage when heat-laminated (except for heat-shrinkable cigarette film which takes advantage of its heat shrinkage properties). It has better overall performance than moisture resistant

BOPP film also has excellent printability. Representative physical properties data are: turbidity <1.5%; gloss >85%; tensile strength ( longitudinal/transverse ) >120/200MPa; elongation at break ( longitudinal/transverse ) <180%/65%; modulus of elasticity of 1700-2500Mpa; brittleness temperature of -50°C.

The Disadvantages Of BOPP Film

- Lower elongation than PP

- Poor heat sealing properties

- Not easy to seal when used independently

- Generally laminated with PE and other films with good heat sealing properties when used.

The Advantages Of BOPP Film

- High tensile strength, good barrier properties, high transparency.

- Due to the orientation of molecules, crystallinity is increased, tensile strength, impact strength, rigidity, toughness, moisture resistance, transparency are all improved, the film’s cold resistance is also improved

- Good air and moisture resistance

- High transparency, good gloss, good printability

- Non-toxic, odourless and tasteless, can be used directly in contact with food and pharmaceuticals.

| Density g/cm3 | 0.91 | Turbidity% | 0.5 ~ 1.2 |

| Melting Point °C | 170 | Heat Shrinkage %(120℃,15min) | 2 ~ 3 |

| Tensile Strength MPa | Longitudinal: ﹥120Horizontal: ﹥200 | Moisture Permeability g/(cm2·24h)(38℃,90%RH) | 5 ~ 8 |

| Elongation At Break% | Longitudinal: 150 ~ 190Horizontal: 50 ~ 70 | Oxygen Permeabilitycm3·100um/(m2·24h)(23℃,0%RH) | 350 ~ 400 |

| Impact StrengthJ /cm | 750 | ||

| Tear StrengthN /mm | 4 ~ 5 | Operating Temperature range °C | -20 ~ 120 |

Bi-oriented polypropylene films are divided into the following categories according to their use.

- General BOPP Films

- BOPP Heat Sealing Films

- BOPP Cigarette Packaging Films

- BOPP Pearlescent Films

- BOPP Metallized Films

- BOPP Matte Films

- BOPP Anti-Fog Films

- BOPP Book Lamination Films

- BOPP Anti-Counterfeit Films

- BOPP Paper Ball Films

Disadvantages: lower elongation than PP, poor heat sealing properties, not easy to seal when used independently, generally laminated with PE and other films with good heat sealing properties when used.

Advantages: high tensile strength, good barrier properties, high transparency. The performance parameters are as follows:

| Density g/cm3 | 0.91 | Turbidity% | 0.5 ~ 1.2 |

| Melting Point °C | 170 | Heat Shrinkage %(120℃,15min) | 2 ~ 3 |

| Tensile Strength MPa | Longitudinal: ﹥120Horizontal: ﹥200 | Moisture Permeability g/(cm2·24h)(38℃,90%RH) | 5 ~ 8 |

| Elongation At Bbreak% | Longitudinal: 150 ~ 190Horizontal: 50 ~ 70 | Oxygen Permeabilitycm3·100um/(m2·24h)(23℃,0%RH) | 350 ~ 400 |

| Impact StrengthJ/cm | 750 | ||

| Tear StrengthN/mm | 4 ~ 5 | Operating Temperature range °C | -20 ~ 120 |

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.