NON-WOVEN FOR PACKAGING BAG

Non-woven bags are a green product, tough, durable, beautiful, breathable, reusable, washable, screen-printed ads, markers, and long service life.Non-woven bags are easier to print patterns than plastic bags, and the color expression is more vivid.

The product is made of non-woven fabric, which is a new generation of environmental protection material with the characteristics of moisture-proof, breathable, flexible, light, non-combustible, easy to decompose, non-toxic and non-irritating, colorful, inexpensive and recyclable. The material can be placed outdoors for 90 days to decompose naturally, placed indoors for up to 5 years, non-toxic, tasteless, and no residual material when burning, so as not to pollute the environment.

OUR CASE STUDIES OF NON-WOVEN PACKAGING BAG

Currently, our custom packaging bags are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom packaging bag fabrication service provides durable and affordable plastic bag that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, Supermarkets, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your custom packaging bag project.

-

PE Biodegradable Material PET Poop Bags

-

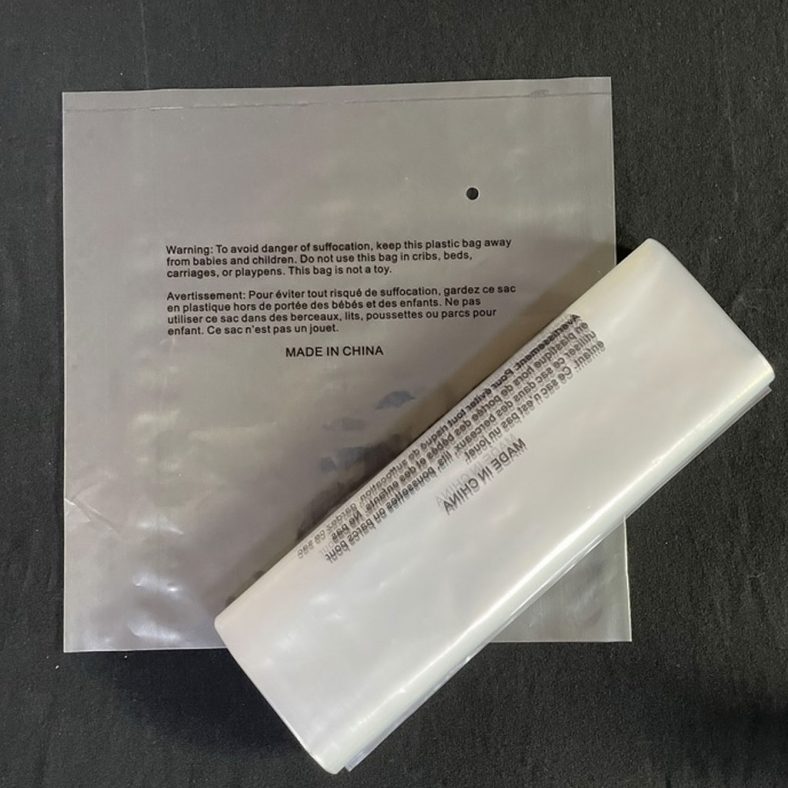

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

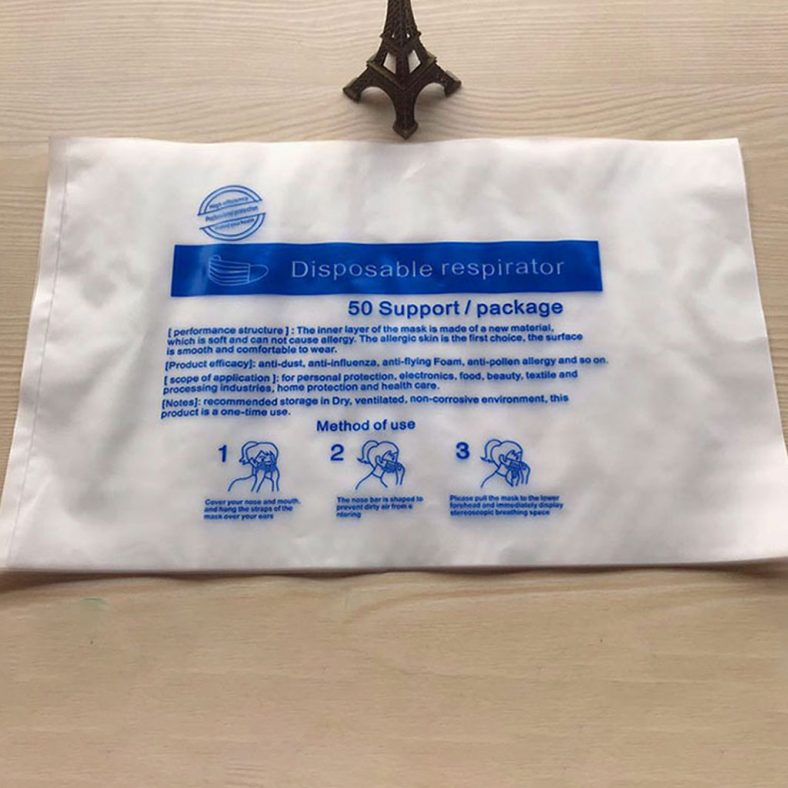

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

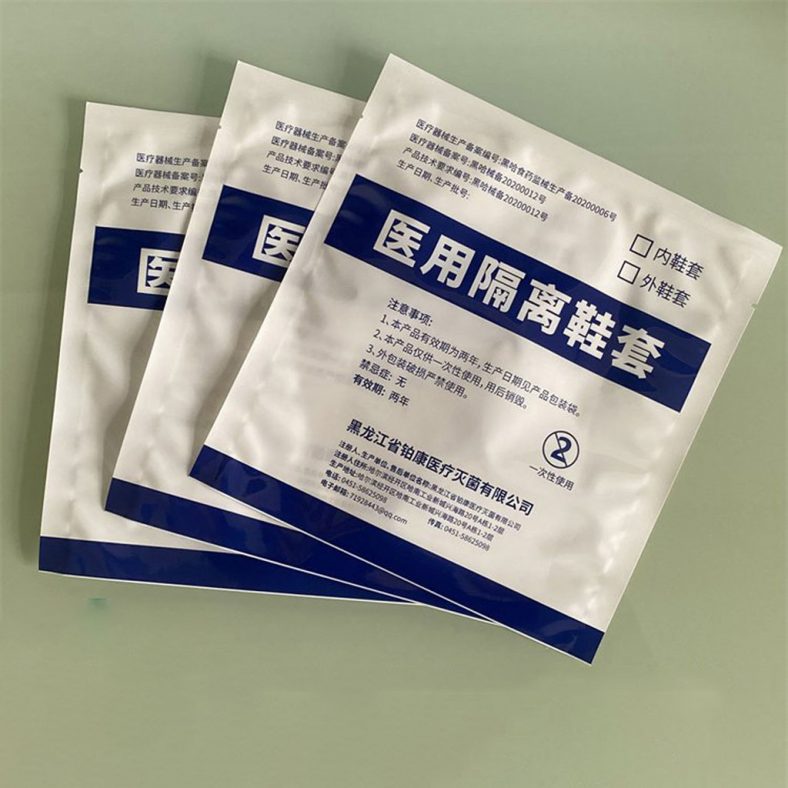

Self Sealing Bag For Medical Shoe Cover

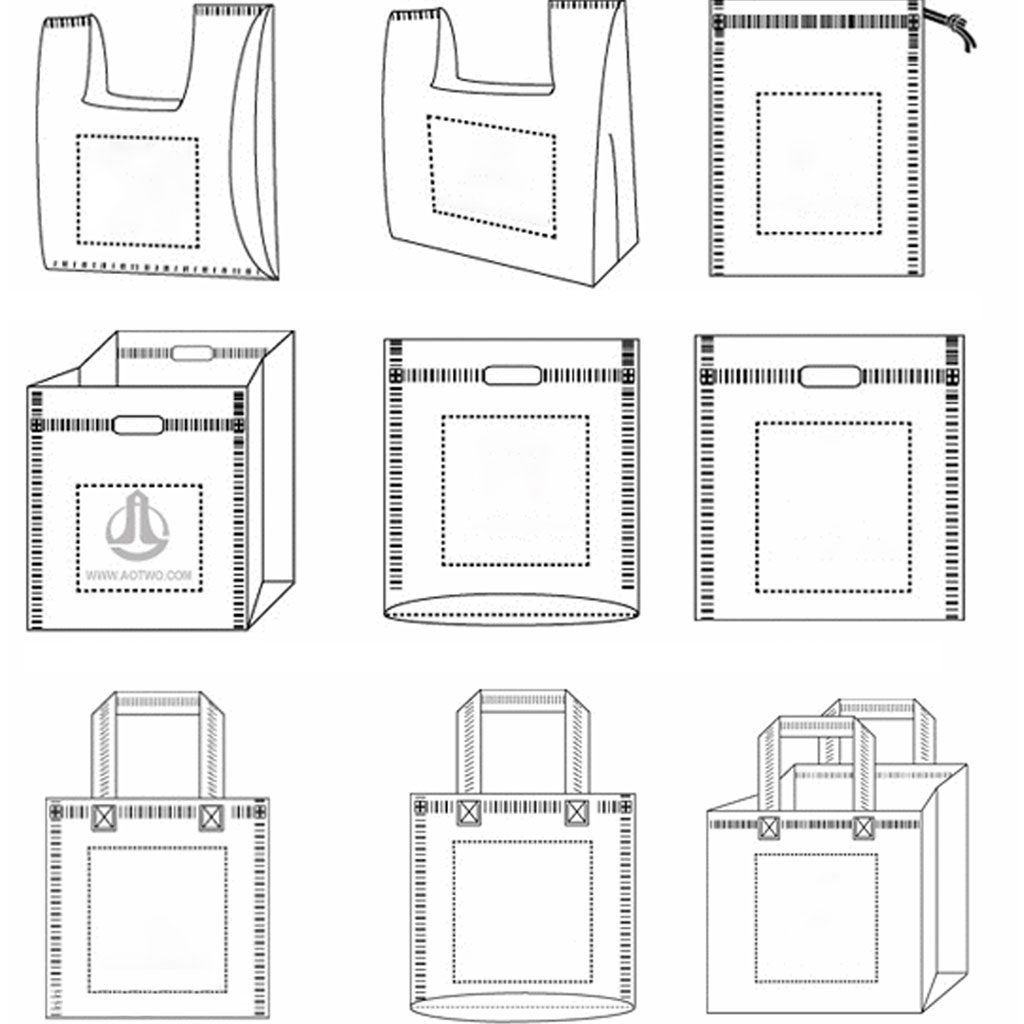

THE TYPE OF NON-WOVEN BAGS

Usually the most commonly used is non-woven tote bags, tote bags of this style are widely used, can be widely used for company holiday activities to promote, business opening celebrations, etc., can also be used for the outer packaging of goods. Such as beverage product packaging, dairy products packaging promotion, etc.

- Flat punching bags (die-cut bags)

- Punching bags with bottom organ

- Non-woven perforated bags with bottom and side accordion

- Singing bags

- Be careful with carry bags with bottom organSelect a carry bag with bottom and side organUndershirt bags

- µVest with bottom and side organ

- Sneaker bag with side organ

- Drawstring bag

- Application laminated bags|laminated bags

- Special shaped environmental bags

In addition, non-woven three-dimensional bags are more popular environmental bags in the market in recent years. It combines the beauty and practicality of tote bags and the low cost of hot press bags. Now, especially large beverage companies, milk companies are using this non-woven three-dimensional bags as the first choice for product packaging.

The PRINCIPLE OF NON-WOVEN BAGS

- Nonwoven fabric is a non-woven fabric, which directly uses polymer slices, staple fibers or filaments formed by various fibrous web forming methods and cementation technology to form new fiber products with soft, breathable and flat structure. Advantages of non-woven bags compared to traditional plastic bags: non-woven bags are inexpensive, environmentally friendly and practical, widely used, and have a prominent advertising position. Suitable for all kinds of business activities and exhibitions and trade fairs, is the ideal advertising and promotional gifts for enterprises and institutions.

- The raw material of non-woven bags is polypropylene, while the raw material of plastic bags is polyethylene, the two substances are similar in name, but the chemical structure is very different. The chemical molecular structure of polyethylene has a strong stability, extremely difficult to degrade, so plastic bags need 300 years to decompose; while the chemical structure of polypropylene is not strong, the molecular chain can easily break, so it can be effectively degraded, and in a non-toxic form into the next environmental cycle, a non-woven bag in 90 days can be completely decomposed.

- Nonwoven fabric is made into a cloth-like product without the weaving process, also called non-woven fabric. Because it is only textile short fiber or filament for directional or random support column, forming a fiber network structure, and then using mechanical, thermal or chemical reinforcement methods can be made. Most of the non-woven bags are made of spunbond non-woven fabric.

- Simply put: non-woven fabrics are not made of one by one yarn interwoven, braided together, but the fibers are directly bonded together by physical means, so when you get your clothes in the sticky weigh, you will find that it is impossible to draw a thread. Nonwoven fabric breaks through the traditional principle of weaving, and has the characteristics of short process, fast production speed, high yield, low cost, wide use, and many sources of raw materials.

- Complex film non-woven bags, the product is cast in a flowing way, the compound is firm, no sticky glue in the compounding process, soft to the touch, no plastic feeling, no skin irritation, suitable for disposable medical sheets, bed sheets, surgical gowns, isolation clothing, protective clothing, shoe covers, and other health protection supplies; this cloth made of bags called complex film non-woven bags.

THE ADVANTAGE OF NON-WOVEN BAGS

Non-woven bags are a new product to replace white waste, with the increase in new energy, the relevant departments to promote environmental protection and energy saving, and environmental pollution is becoming increasingly serious, in order to get rid of this white pollution, so that our life is better, many environmentally conscious people thought of a new product – non-woven bags, and its advantages are also there for all to see. Woven shopping bags are non-woven fabric made of plastic, many people think that called cloth is a natural material, in fact, it is a misunderstanding. Sewn nonwoven bag is a kind of dry nonwoven fabric, sewn method is the use of warp knitting coil structure on the fiber network, yarn layer, non-textile materials (such as plastic sheet, plastic thin metal foil, etc.) or their combination of reinforcement to make nonwoven fabric.

Commonly used non-woven raw materials for polypropylene (English abbreviation PP, commonly known as polypropylene) non-woven bags or polyethylene terephthalate (English abbreviation PET, commonly known as polyester), environmental protection and ordinary plastic shopping bags, as well as are not fully degradable. In terms of specific cost performance, the same conditions of non-woven bags are not as strong as plastic bags, and not waterproof, and its price is several times higher than plastic bags. Needle punching nonwoven bags: is a kind of dry nonwoven fabric, needle punching nonwoven fabric is the use of puncture needles puncture effect, the fluffy fiber network reinforced into cloth. In particular, PP with plastic shopping bags with the same PE, are among the five general plastic varieties, belonging to the 50 years can not be degraded plastic varieties.

The production cost of non-woven bags mainly includes two parts, one is the cost of raw materials, the second is the cost of processing cloth bags. In the market can buy the non-woven fabric its specifications are very many, and the cost is not the same. Hydroentanglement nonwoven bags: is a high-pressure micro-fine water jet to one or more layers of fiber network, so that the fibers are entangled together, so that the fiber network can be reinforced and have a certain strength. Thermally bonded nonwoven bag: It means adding fibrous or powdered hot melt bonding reinforcement to the fiber web, and then the fiber web is heated and melted and cooled to reinforce the cloth. Non-woven bags are environmentally friendly products, is a more common packaging bags, mainly used for shopping, packaging, advertising, electronics, clothing, decoration and other products. The biggest feature of non-woven fabric is that it has an environmental function that plastic products do not have, and the time it takes to be naturally degraded is far less than plastic bags, therefore, non-woven bags made of non-woven fabric are also publicly regarded as the most affordable environmentally friendly shopping bags.

- Economic Benefits:From the release of the plastic restriction, plastic bags will begin to gradually withdraw from the packaging market of goods, replaced by non-woven bags that can be used repeatedly. Non-woven bags are easier to print patterns than plastic bags, the color expression is more vivid. Plus can be used repeatedly a little, you can consider the non-woven bags with more beautiful patterns and advertising than plastic bags, because the ability to use repeatedly loss rate lower than plastic bags, resulting in non-woven bags instead of more cost effective, and bring more obvious advertising benefits.

- Firm: traditional plastic bags, in order to save costs so the material is thin, easy to break. But if in order to make him more solid, it must cost more. The emergence of non-woven bags solve all the problems of non-woven bags, toughness, not easy to wear. There are a lot of laminated non-woven bags, but also has a firmness, but also has a waterproof, feel good, beautiful appearance of a bit. Although the cost of a single compared to plastic bags up a little, but its service life of a non-woven bag can be hundreds, or even thousands of tens of thousands of plastic bags.

- More Promotional Advertising Effect: a beautiful non-woven bag, not just a commodity packaging bag. Its exquisite appearance is more lovable, can be transformed into a fashionable and simple shoulder bag, become a beautiful scenery on the street. Plus its solid, waterproof, non-stick characteristics will become the first choice of customers to go out, in such a non-woven bag, can be printed on your company’s logo or advertising, its advertising effect is self-evident, the real small investment into a big return.

- Non-Woven Bags More Environmental Protection Public Welfare Value: the issuance of plastic restrictions, is to solve the problem of environmental protection. Non-woven bags are used repeatedly, greatly reducing the pressure of waste transformation. So double known as environmental bags, coupled with the concept of environmental protection, more able to reflect the image of your business, and the pro-people effect. Thus bringing the potential value of more than money can replace.

THE PRODUCTION PROCESS OF NON-WOVEN BAGS

- Hydroentanglement: The hydroentanglement process is a high-pressure micro-fine water jet onto one or more layers of fiber webs, which entangles the fibers with each other, thus reinforcing the web with a certain strength.

- Thermally Bonded Nonwoven: Thermally bonded nonwoven refers to the addition of fibrous or powdered hot melt bonding reinforcement to the fiber web, which is then heated and melted and cooled to reinforce the cloth.

- Air-flow Web Formation:Air-flow web formation nonwoven can also be called as dust-free paper and dry paper nonwoven. It adopts the air flow forming technology to open the wood pulp fiber board into a single fiber state, and then use the air flow method to make the fiber condense on the forming curtain, and then the fiber net is reinforced into cloth.

- Wet Nonwoven:Wet nonwoven fabric is placed in the aqueous medium to open the fiber raw materials into a single fiber, while making different fiber raw materials mixed, made of fiber suspension pulp, suspension pulp transported to the web-forming mechanism, fiber in the wet state into the web and then reinforced into cloth.

- Spunbond Nonwoven:Spunbond nonwoven is formed after the polymer has been extruded and stretched to form a continuous filament, the filament is laid into a web, and the fiber web then undergoes its own bonding, thermal bonding, chemical bonding or mechanical reinforcement methods to make the fiber web into a nonwoven fabric.

- Meltblown Nonwoven:The process of meltblown nonwoven: polymer feeding — melt extrusion — fiber formation — fiber cooling — web formation — reinforcement into cloth.

- Needle Punching Nonwoven:Needle punching nonwoven is a kind of dry nonwoven fabric. Needle punching nonwoven fabric uses the piercing effect of the felting needle to reinforce the fluffy fiber network into cloth.

- Sewn Nonwoven: Sewn nonwoven is a type of dry nonwoven. The sewn method uses the warp-knitted coil structure to reinforce the fiber web, yarn layer, non-woven materials (e.g. plastic sheet, plastic foil, etc.) or their combination to make a nonwoven fabric.

THE APPLICATION OF NON-WOVEN BAGS

According to the different uses of the product can be divided into.

- Non-woven bag series: non-woven environmental bags, non-woven handbags, non-woven shopping bags, etc.

- Non-woven bag series: non-woven document bags, environmental protection shopping bags, packaging bags, non-woven bags

- Nonwoven products series: nonwoven storage boxes, nonwoven storage boxes, nonwoven suit covers and nonwoven suit covers.

- Singing jewelry bags series: gift bags, jewelry bags, velvet bags, perfume bags, pen bags, jewelry bags, etc.

- Be careful with apron series: advertising aprons, polyester aprons, cotton aprons, PVC aprons, hanging net aprons.