Custom Gravure Printing

Gravure is a plate making technique in which the image is engraved and recessed from the surface, the ink is filled directly into the recesses of the gravure plate and then embossed directly onto the substrate. Gravure printing is characterised by a thick, well-defined ink layer and a strong sense of three-dimensionality.

At the same time, gravure printing is carried in ink by means of individually engraved pits required for the product, which is not easily imitated or forged and has strong anti-counterfeiting properties. Gravure printing is mainly used for the printing of flexible packaging, and is now widely used on bags for food and bags for the pharmaceutical industry. It has a wide range of substrates, which can be paper, plastic, and also high-grade tin foil wrapping paper, etc.

ISO 9001:2000 & ISO 9001:2008 certified Gravure printing services for packaging products.Capabilities include three color printing, web width to 65, two side & one pass printing, gas & Infrared heaters with temperature range of 400 degrees to 1500 degrees, hot roll temperature to 250 degrees & chill roll temperature from 50 degrees to 60 degrees. Capable of handling parts from 15 in. to 63 in. width, 6 mil. to 25 mil. thickness and roll dia. up to 40 in. Medical and pharmaceutical packaging, food manufacturing, banding, direct mail, confectionery bakery, thermoforming, cosmetic and personal care industries served.

-

PE Biodegradable Material PET Poop Bags

-

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

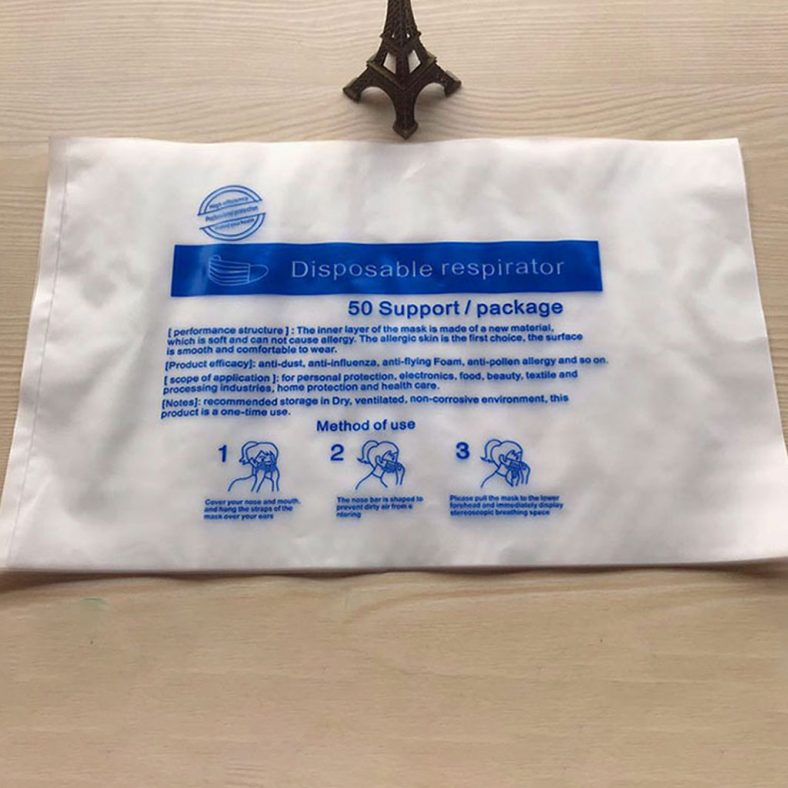

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

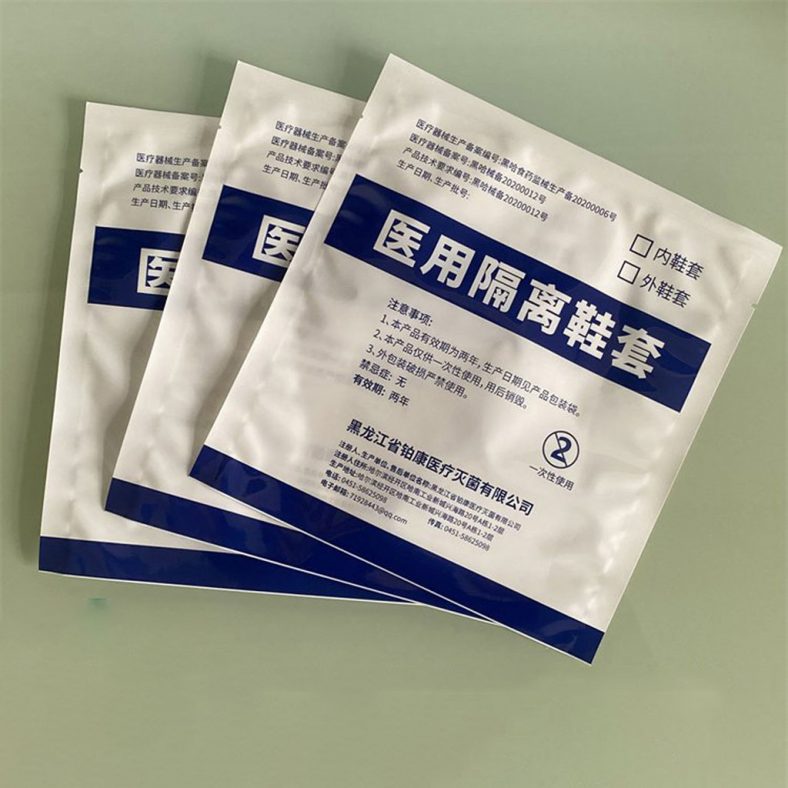

Self Sealing Bag For Medical Shoe Cover

Gravure printing is one of the four major printing methods. Gravure printing is a direct printing method, it will be the ink contained in the pit of the intaglio plate directly embossed on the substrate, the printed picture of the thickness of the level is determined by the size and depth of the pit, if the pit is deep, it contains more ink, embossed on the substrate left on the thicker layer of ink; on the contrary, if the pit is shallow, it contains less ink, embossed on the substrate left on the thinner layer of ink. Gravure printing plates are made up of a pit corresponding to the original text and the surface of the printing plate.

When printing, the ink is filled into the pit, the ink on the surface of the plate is scraped off with a scraper, and there is a certain pressure contact between the plate and the substrate, which transfers the ink from the pit to the substrate and completes the printing. Gravure printing as a printing process, with its printing products ink layer thick, bright colours, high saturation, high printing plate resistance rate, stable print quality, fast printing speed and other advantages in the printing and packaging and graphic publishing field occupies an extremely important position.

From the application point of view, in foreign countries, gravure printing is mainly used in magazines, catalogues and other fine publications, packaging printing and printing of banknotes, stamps and other valuable securities, but also in special areas such as decorative materials; in China, gravure printing is mainly used for flexible packaging printing, with the development of domestic gravure printing technology, has also been widely used in paper packaging, wood grain decoration, leather materials, pharmaceutical packaging. Of course, gravure printing also has limitations, its main disadvantages are: pre-press plate making technology is complex, long cycle time, high plate making costs; due to the use of volatile solvents, the content of harmful gases in the workshop is high, which is harmful to the health of workers; gravure printing practitioners require relatively high treatment

Gravure Printing due to the high degree of automation of the printing machine, plate quality, and thus the process operation than lithographic printing is simple and easy to master, the process flow is as follows: pre-press preparation → on the plate → adjust the rules → formal printing → post-press processing

The Pre-press Preparation Of Gravure Printing

Preparation for gravure printing includes the preparation of substrates, inks, squeegees, etc., according to the requirements of the construction sheet, and also the lubrication of the printing press.

- Plastic films are the main substrates for gravure printing. Commonly used plastic films include polyethylene, polypropylene and PVC. Because of the smooth surface of plastic film and poor adhesion of ink, the surface of the film should be treated before printing. Corona treatment is generally used, the method is to pass the plastic film in two electrodes, the use of high-frequency oscillation pulse to force the air ionisation to produce discharge phenomenon to form a corona, free oxygen atoms and oxygen molecules combined to generate ozone, so that the film surface to form some strong group and the naked eye invisible “burr”, so as to improve the film’s This increases the surface tension and roughness of the film, which facilitates the adhesion of inks and adhesives.

- Gravure printing, using solvent volatile ink, low viscosity, good fluidity and strong adhesion. Commonly used solvents are toluene, xylene, petrol, alcohol, etc. Before printing, an appropriate amount of solvent release is added to the ink, which is best filtered before use.

- The most important feature of the gravure printing machine is the use of scraping knife, scraping the blank part of the printing plate ink. The squeegee is a special steel blade 60mm to 80mm wide and 1000mm to 1500mm long (depending on the size of the plate cylinder). The scraper blade must be straight, if there is a “small crescent” type of scar, it will appear in the printing sheet a very wide slant, that is, the phenomenon of empty bars.

- The printing plate is the basis of printing, directly related to the quality of printing, the plate needs to be reviewed before the plate. Check whether the network is neat, complete, chrome-plated printing plate whether the phenomenon of de-chromium, text printing plate, the requirements of the line is intact, not broken pen less channel. The printing plate can only be installed on the printing machine after detailed inspection.

On The Version Of The Operation

Adjusting The Rules

Formal Gravure Printing

The Originals Of Gravure Printing

The Inks Of Gravure Printing

The Printing Plates Of Gravure Printing

The Substrates Of Gravure Printing

The Machinery Of Gravure Printing

- Advantages : Ink expressiveness of about 90%, rich in shades. Strong colour reproduction. Strong plate resistance. Large print runs. A wide range of papers can be used, and materials other than paper can be printed.

- Disadvantages: the cost of making plates is expensive, as is the cost of printing, the work of making plates is more complicated, and a small number of prints is not suitable.

- Gravure Printing Applications:Engraved intaglio printing, because of its fine lines, and not easy to counterfeit, so are used in the printing of securities, such as banknotes, stocks, gift certificates, stamps and commercial credentials or stationery, etc.. Because of the high cost of plate making and printing, it was rarely used for general printing. As for photogravure, although its plate making process is more complicated and its cost is also more expensive, it is not suitable for printing a small number of prints, and is generally used in large quantities of printed matter, such as colour magazines and the currently popular building materials printing, etc., are extremely suitable. Gravure printing, because of the use of high-speed rotary machine type, not only the speed and printing out of the ink film is far thicker than the letterpress or lithographic.

According to the existing practical situation in the industry, there are three ways of digital plate making for gravure printing: the electronic engraving machine method, the laser engraving film and post-etching treatment method, and the laser direct ablation plate making method for electroplated alloys.

Use Electronic Engraving Machine For Gravure Printing

Use Laser Engraving And Post-Etching For Gravure Printing

Direct Laser Ablation Of Electroplated Alloys

The ink carrier in intaglio printing is a pit carved into the printing plate, the shape of the pit is exactly the same as the original artwork, and there is no ink on the surface of the plate. When the plate comes into contact with the substrate, the ink in the crater is transferred to the surface of the substrate to complete the printing process. Gravure printing therefore has a number of unique features that distinguish it from other printing methods, which are discussed below.

Anti-Counterfeiting

Wide Range

High Quality Printing

High-volume printing

One of the basic printing methods. The plate is printed with a lower graphic than the blank part, and the full plate is inked during printing, then the page is scraped so that only the graphic part is left with ink, which is transferred to the substrate and becomes the printed product. It can be divided into 3 categories: engraved intaglio, photo-etching intaglio and electronic engraving intaglio.

Engraved intaglio was developed from the art of printmaking. Invented by the Italian goldsmith M. Finiguerra in 1452. At the beginning it was all hand engraving, later there was chemical etching and in recent times machinery has been used as far as possible. The plate consists of dots and lines of varying shades and thicknesses. The printed lines are slightly convex, glossy and clear, and can prevent forgery, so it is mostly used for printing banknotes, stamps and other valuable securities.

Photographic etching intaglio In the late 19th century, the Bohemian-born painter K. Klick invented photogravure and intaglio printing with a scraper, using the results of his predecessors’ photogravure and carbon paper overprinting. The inking part of the plate is a regular arrangement of tiny holes (mesh cavities), generally square in shape and of the same size, but with different depths and different ink capacities. It is the most common type of intaglio printing, so it is also known as traditional photogravure. For more than half a century, several new photogravure plates have been developed, such as the reference offset dot structure, which has different inking hole sizes and consistent or inconsistent depths, with better printing quality.

Electronic engraving gravure plates In the mid-20th century, gravure electronic engraving machines began to exist, which use a scanning head and a computer-controlled diamond engraving knife to engrave the inking holes on the cylinder in the shape of an inverted pyramid, with variations in size and depth. The printing quality is as good as that of photogravure, and has the advantages of simple operation, short plate making time and no waste disposal problems.

Most modern gravure printing plates are made on the surface of a circular cylinder, using a circular press. Usually the impression cylinder is on top and the plate cylinder is underneath. The lower part of the plate cylinder is dipped in the ink tank, and the layout is inked from the tank (also inked with an ink pump or inked by an ink roller dipped in the ink tank to the layout). Above the ink tank with a thin steel scraper pressed against the surface of the printing plate cylinder, scraping the ink on the layout without graphics (also used to reverse the rotation of the wiping ink roller wipe). Remain in the layout of the inking holes (or lines) within the ink, in the turn to the two cylinders tangential transfer to the paper through the place (plastic film, foil, etc.), printed on the text.

Reproduction of monochrome or colour photographic manuscripts compared with offset or copperplate letterpress, etc., has the advantages of thick ink layers, rich layers, good printing quality, low waste paper rate, printing plate resistance to printing, can be stored for a long time, especially in coarse paper, cellophane, plastic film, metal foil on the printing effect is good. But the gravure plate making time is long and costly, so only the high quality requirements of colour pictures, picture books, pictorials, booklet illustrations, postcards, trademarks, packaging and decoration, securities, architectural and decorative materials, etc. are suitable for gravure printing. And the number of printed products is large, with gravure printing is more cost-effective. Also because of the printing of small text quality is not good, so the text-based books and magazines do not use gravure printing.

Gravure ink shall be easy to enter the inking hole of the printing plate and transferred to the paper, so the liquidity should be good, commonly used volatile benzene as a solvent. To prevent solvent pollution of the air and fire, must pay attention to the airtight pollution sources, recovery of solvent and ventilation of the workplace. For the research and application of water-based gravure ink that does not reduce the quality of printing, both at home and abroad are actively exploring.

The types of gravure printing are divided into two categories according to the plate making method: engraved gravure and etched gravure

Engraved Gravure

Gravure engraving is the use of an engraving knife to directly engrave a pit on the surface of the plate cylinder corresponding to the original artwork, and can be divided into manual engraving gravure, mechanical engraving gravure and electronic engraving gravure according to the control method of the engraving knife.

Manual Gravure Engraving

Mechanical Gravure Engraving

Electronically Engraved Intaglio Plates

Etching Gravure

Gravure plates are made by chemically etching an ink pit on the surface of the printing cylinder in accordance with the original artwork. Depending on the method of conversion of the original artwork, etched gravure can be divided into etched gravure, photogravure and dot gravure.

- Etched intaglio plates are made by a combination of engraving and etching. In other words, the shape of the original artwork is first engraved by hand, and then the gravure plate is made by etching.

- Photogravure plates are widely used and are the most used plates in gravure printing, mainly for printing picture plates etc.

- Gravure plates are mainly used for packaging and decoration printing and building materials printing.

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.