Anti Static Bags Suppliers

Anti-static bags are also known as electromagnetic shielding packaging bags. In order for the plastic to be shielded from electromagnetic waves, it is metalised, using a material called an antistatic agent.Please note that the shielding of electromagnetic waves here does not mean that the electromagnetic waves can be completely shielded out like metal sheets, but only to reduce the damage of electromagnetic waves. Antistatic agents are divided into two categories according to the method of application: external coating type and internal addition type.

Anti Static Bags efficiently electromagnetic shielding and other funcation. Wonder Plastic offers safe and durable Anti Static Bags in bulk. Our Anti Static Bags have different exquisite designs that are suitable for every occasion.

We offer clear and transparent anti static bags, yet some prefer to have color tints. Thus, we also offer aluminum foil anti static bags in any colors. More so, if the things you need are not available, feel free to get in touch with us. We offer full assistance in customizing anti static bags, from color tints to sizing capacity.

-

PE Biodegradable Material PET Poop Bags

-

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

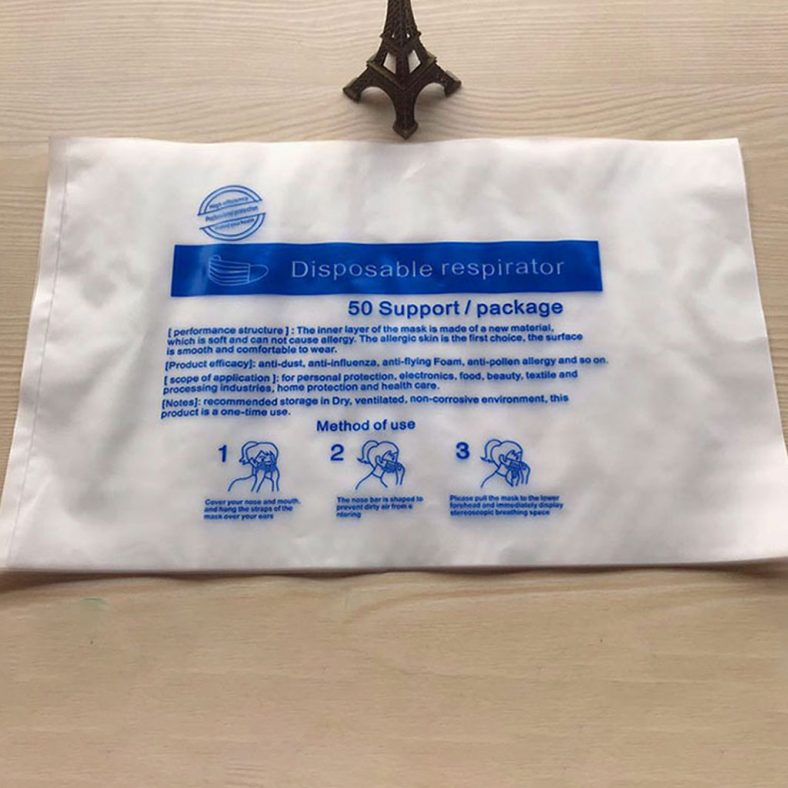

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

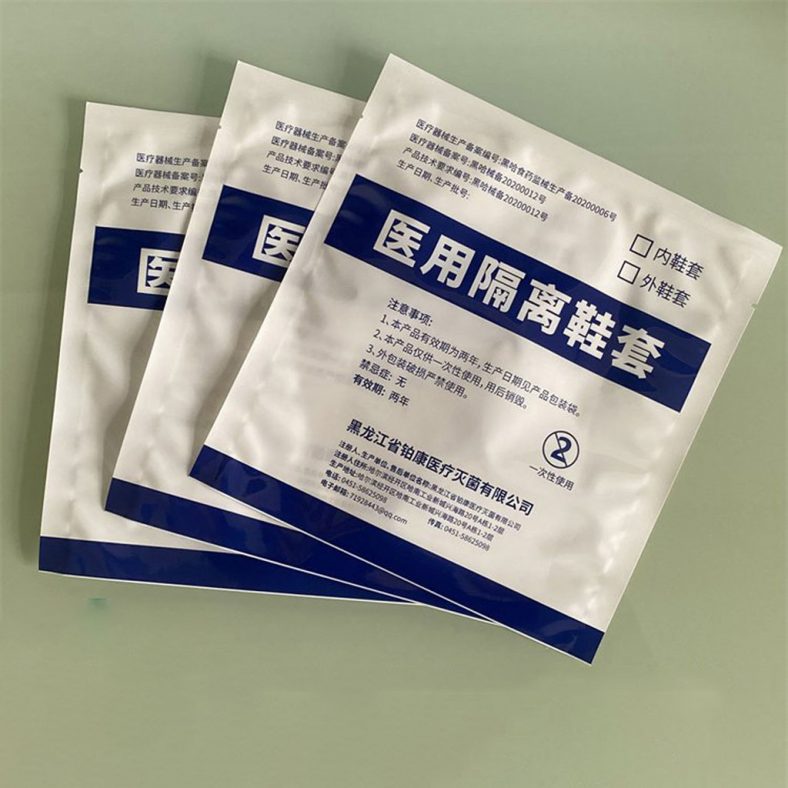

Self Sealing Bag For Medical Shoe Cover

Usually the ordinary plastic bags used by everyone are generally made of insulating materials, while the bags containing sensitive devices are designed to be made of anti-static substances, generally called anti-static bags, which can also be called anti-static shielding bags, silver grey transparent static bags, anti-static moisture-proof bags.

Anti-static shielding bags it is made of composite product performance, widely used in all types of pc boards, computer motherboards, sound cards, graphics cards, network cards and electrostatic sensitive high-tech electronic products packaging. The anti-static packaging material is made of multi-layer material by compound coating, the inner layer is the heat sealing layer, sealing strength than the general material sealing strength is twice as high; the middle layer is the high strength mechanical layer, with excellent mechanical function; the outer layer is the conductive layer. The material is compatible with the relevant chemical products and has good performance. It will not react chemically with the packaged products during the packaging and storage process, and can be directly used for the contact packaging of the relevant products. It has excellent overall mechanical properties and meets the requirements of packaging strength as proven by mechanical strength and packaging and transport drop tests. It has good processability, the conductive layer is coated and can be processed into any shape according to user requirements. According to the solvent migration test and aging performance test, the service life of the material is 18 years. China’s anti-static bag packaging materials to reach international standards

Anti-static bags provide maximum protection for static sensitive components from potential static hazards, their unique Faraday cage construction creates an “induction shield” effect to shield the contents of the bag and anti-static effects, the outer wear resistant metal coating and inner vinyl material, through a complex process to achieve the best possible electrostatic shielding protection. The semi-transparent heat-sealed bag type technology, can clearly identify the contents of the bag.

Anti-Static Bag Recommended Range Of Application: for anti-static requirements of electronic products packaging, such as various types of PC boards, IC integrated circuits, optical drives, hard disks, electronic components, etc..

- a. Protection against the generation of electricity by friction.

- b. Protection from electrostatic fields.

- c. Protection against direct discharge from contact with charged bodies or with charged objects.

It is difficult to make a material with all of the above properties at the same time, and often requires a combination or compound of different materials to achieve the required purpose. Any material that can limit electrostatic charge build-up or can be protected from external electrostatic charges by safely dissipating electrostatic charges or shielding parts can be used as ESD protective packaging materials.

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.