EVA FOR PACKAGING BAG

EVA hot melt adhesive is a solvent-free, water-free, 100% solid fusible polymer, solid at room temperature, heated and melted to a certain degree into a liquid adhesive that can flow and has a certain viscosity, its melt is light brown translucent body or this white.

The main component of hot melt adhesive, i.e. the basic resin, is copolymerization of ethylene and vinyl acetate under high pressure, and then it is made into hot melt adhesive with tackifier, viscosity adjuster and antioxidant.

EVA is a plastic material consisting of ethylene (E) and vinyl acetate (VA). The ratio of these two chemicals can be adjusted to meet the needs of different applications. The higher the vinyl acetate (VA content) content, the higher the transparency, softness and toughness.

ETHYLENE/VINYL ACETATE COPOLYMER(EVA)

Ethylene vinyl acetate copolymer (also known as ethylene – a vinyl acetate copolymer) is made from ethylene (E) and vinyl acetate (VA) copolymerization, the English name; Ethylene Viny Acetate, referred to as EVA, or E / VAC. polymerization methods with high-pressure ontogenic polymerization (for plastics), solution polymerization (PVC processing aids). Emulsion polymerization (adhesives), suspension polymerization.

Ethylene acetate (VA) content higher than 30% using emulsion polymerization, ethylene acetate content is low with high-pressure insta-polymerization. EVA has a wide range of uses. In general, ethylene acetate content in less than 5% of EVA, its main products are films, wire and cable LDPE modifiers, adhesives, etc.; ethylene acetate content in 5%-10% of EVA products such as flexible films; ethylene acetate content in 20%-28% of EVA, mainly for hot melt adhesives and coating products; ethylene acetate in 5%-45%, the main products for film ( including agricultural films) and sheets, injection and molding products, foam products, hot melt adhesives, etc. It is widely used in the fields of foaming shoes, functional shed film, packaging mold, hot melt adhesive, wire and cable, and toys.

OUR CASE STUDIES OF EVA PACKAGING BAG

Currently, our custom packaging bags are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom packaging bag fabrication service provides durable and affordable plastic bag that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, Supermarkets, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your custom packaging bag project.

-

PE Biodegradable Material PET Poop Bags

-

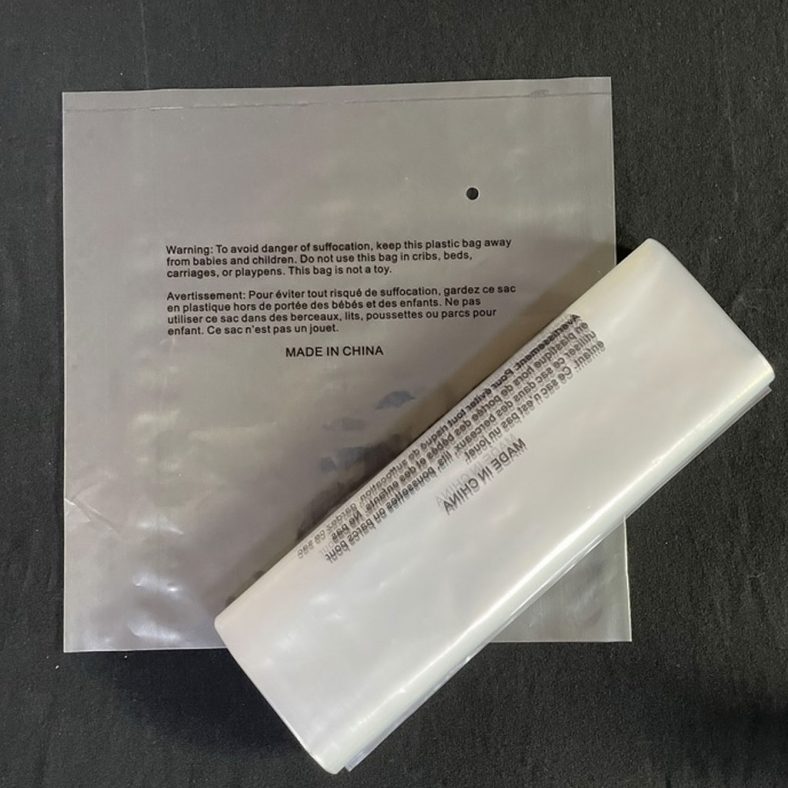

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

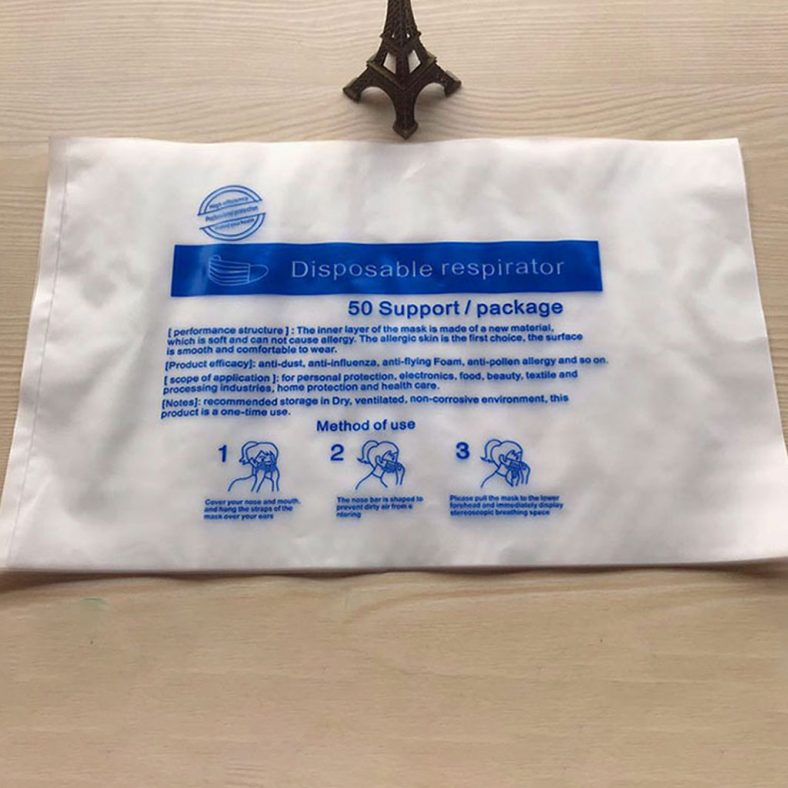

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

THE PRODUCT BACKGROUND OF EVA MATERIAL

Hot melt adhesive is a solid solvent-free adhesive made of thermoplastic resin or thermoplastic elastomer as the main component, with the addition of plasticizer, tackifier resin, antioxidant, flame retardant and filler, etc., mixed by melting. Because of its non-toxic, non-environmental pollution, easy to prepare and other advantages to become the direction of the development of the adhesive market, the world’s annual production has been on the rise, its growth rate in all types of adhesives for the highest, more and more diverse varieties, the application is more and more extensive.

Bayer, ICI, Monsanto and other companies have produced such products.

EVA hot melt adhesive cohesion, melt surface tension is small, almost all substances have hot glue force, and has excellent chemical resistance, thermal stability, weatherability and electrical properties, bonding quickly, wide range of applications, non-toxic, non-polluting and other characteristics of the “green glue”, attracting more and more attention.

THE FEATURES OF EVA MATERIAL

- Usually solid at room temperature, melt into liquid when heated to a certain degree, once cooled to below the melting point, and quickly become solid, (i.e., and curing).

- With fast curing, low public hazard, strong adhesion, the glue layer has both certain flexibility, hardness, and toughness.

- The glue layer can be heated and melted again after it is cooled and cured on the bonded object, and then become adhesive again with the bonded object, which has certain re-adhesive property.

- When using, as long as the hot melt glue is heated and melted into the required liquid state and applied to the object to be bonded, the bonding and curing can be completed within a few seconds after pressing together, and the degree of hardening and cooling and drying can be achieved within a few minutes.

- Perforated tote bag is a hole at the top of the flat pocket at the appropriate location to facilitate the lifting of the bag.