PE FOR PACKAGING BAG

PE is the abbreviation of polyethylene, is a thermoplastic resin made of ethylene by polymerization. In industry, it also includes copolymers of ethylene and a small amount of α-olefin; it is a transparent plastic bag, which can be used for clothing, bags, electronic products and other packaging.

- Polyethylene, with excellent low temperature resistance (the minimum operating temperature can reach -70 ~ -100 ℃), good chemical stability, can resist the erosion of most acids and bases (not resistant to acids with oxidizing properties), insoluble in general solvents at room temperature, water absorption is small, excellent electrical insulation properties

- Polyethylene for environmental stress (chemical and mechanical effects) is very sensitive, poor heat aging resistance.

- The properties of polyethylene vary from species to species, depending mainly on the molecular structure and density.

- Different production methods can be used to obtain products with different densities (0.91-0.96g/cm3).

OUR CASE STUDIES OF PE PACKAGING BAG

Currently, our custom packaging bags are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom packaging bag fabrication service provides durable and affordable plastic bag that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, Supermarkets, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your custom packaging bag project.

-

PE Biodegradable Material PET Poop Bags

-

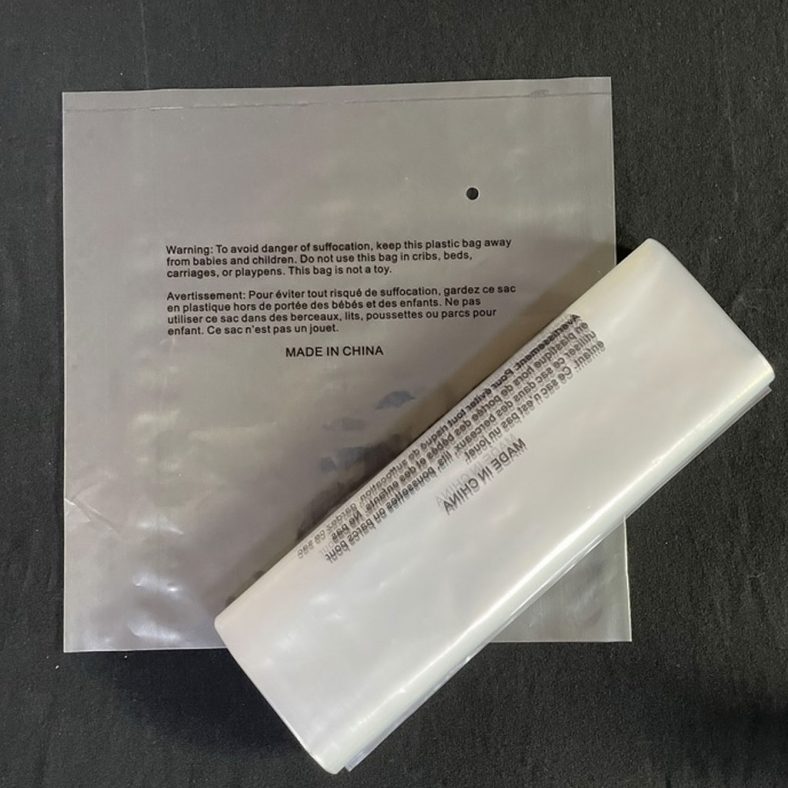

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

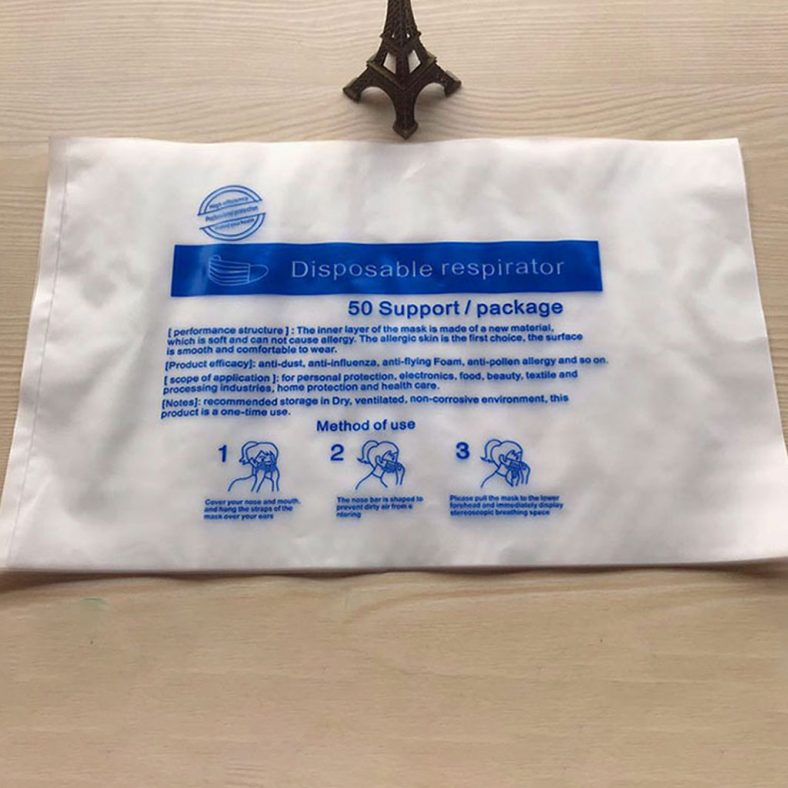

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

THE APPLICATION OF PE MATERIAL

PE is very versatile, mainly used to manufacture films, containers, pipes, monofilaments, wires and cables, daily necessities, etc., and can be used as high-frequency insulation materials for television, radar, etc.

THE TYPE OF PE MATERIAL

According to the material: PE is divided into LDPE, LLDPE and HDPE, etc.

According to the production process is divided into: PE flat pockets, self-sealing bags, chain bags, envelope bags, perforated tote bags, tote bags, zipper bags, PE film.

- PE flat bags for the simplest production process, by the machine after blowing film, and then to the bag-making machine above the cut into a bag, the bottom seal.

- Self-sealing bags are blown by the machine with a bone strip, can be manually sealed. Different from the chain-locked bags, the two bags are generally easy to confuse.

- Chain-locked bags are made of PE film, plus 2 clip chain on top (this clip chain is a separate out) to make the bag, the bag generally has a relatively wide indentation on both sides, while the self-sealing bags are not. Self-sealing bags printed with fewer colors, while the clip chain bags can be printed with complex patterns.

- Envelope bag is like an envelope with a tongue, stick a strip of tape on the tongue, fold over the bag can be sealed. General clothing category with more. There are also courier bags is actually a kind of envelope bags.

- Perforated tote bag is a hole at the top of the flat pocket at the appropriate location to facilitate the lifting of the bag.

- Hand-held bags are to be added to the top of the bag plastic film strip, to facilitate the lifting of the bag, this process consumes labor, the cost is relatively high.

- Zipper bag is to put a zipper chain on the bag closure and bring the zipper cap.

- PE film is the machine blown out of the film is not made into a bag. Also divided into winding film and shrink film.

Commonly used in the market are counted by individual and counted by length (roll).

(a) pouches are mainly used for small accessories packaging, electronic products accessories bag more anti-static effect, the mouth of the bag is divided into flat and self-sealing structure, the latter is also known as bone pockets (PE bone bags) or dense bags;.

(Volume) bags have the need to cut their own (for material packaging) and print cutout (for supermarkets).

Another PE material cling film can also be called PE bags, note that direct contact with food cling film must be used PE material (the other is generally PVC), safer for the human body.

The difference: PVC cling film is stronger than PE cling film in terms of transparency, stretching and viscosity. PVC cling film has a black flame when burned with fire, black smoke, pungent smell, no oil dripping, and will automatically go out after leaving the fire. PE cling film burns with a yellow flame, is odorless, drips oil, and can continue to burn after leaving the fire.