Custom Box, Gaylord & Tote Liners

Box liners, Gaylord liners, and tote liners are protective materials used to line containers, such as boxes, Gaylord containers, and totes, to prevent the contents from coming into direct contact with the container itself. These liners are often used to protect the contents from moisture, dust, dirt, and other contaminants that may be present in the container or the surrounding environment. They are also used to prevent damage to the container itself, such as scratching or staining.Box liners are thin sheets of material that are used to line boxes or other containers. They are often made of polyethylene or other plastic materials and are used to protect the contents of the box from moisture and other contaminants. Box liners are often used to protect food products, pharmaceuticals, and other sensitive materials during shipping and storage.

Gaylord liners are similar to box liners, but they are designed to fit into Gaylord containers, which are large, heavy-duty containers used for bulk storage and shipping. Gaylord liners are typically made of stronger, more durable materials than box liners, such as heavy-duty polyethylene or polypropylene, to withstand the weight and volume of the contents being stored.

Tote liners are used to line totes, which are large, stackable containers used for bulk storage and transportation. Tote liners are typically made of durable materials, such as polyethylene or polypropylene, to protect the contents from moisture and other contaminants and to prevent damage to the tote itself.

In summary, box, Gaylord, and tote liners are protective materials used to line containers to protect the contents from moisture, dirt, and other contaminants and to prevent damage to the container itself. They are used in a variety of industries, including food, pharmaceuticals, and manufacturing, to protect sensitive materials during shipping and storage.

-

PE Biodegradable Material PET Poop Bags

-

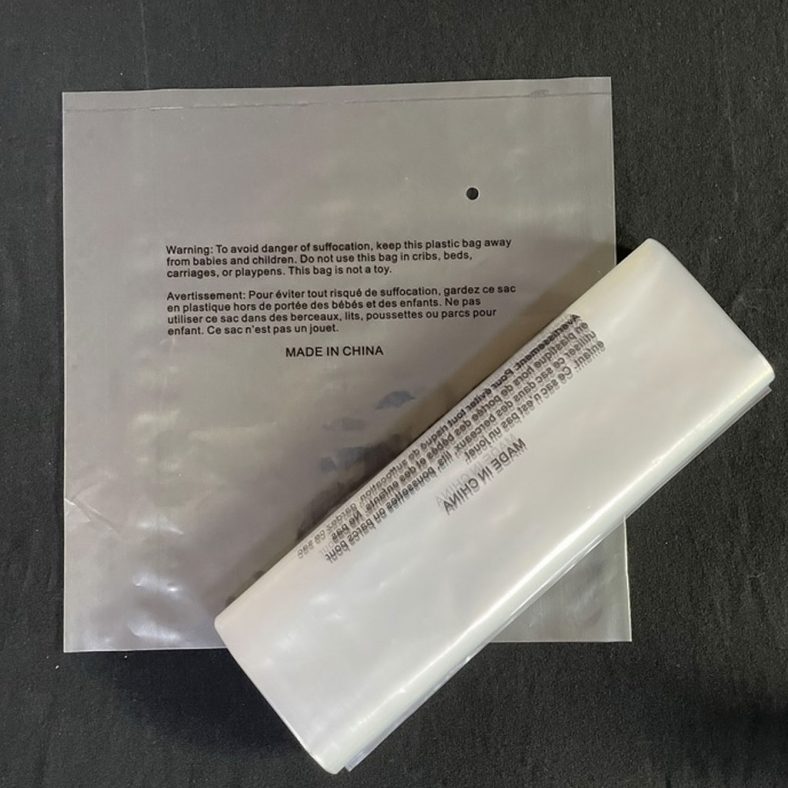

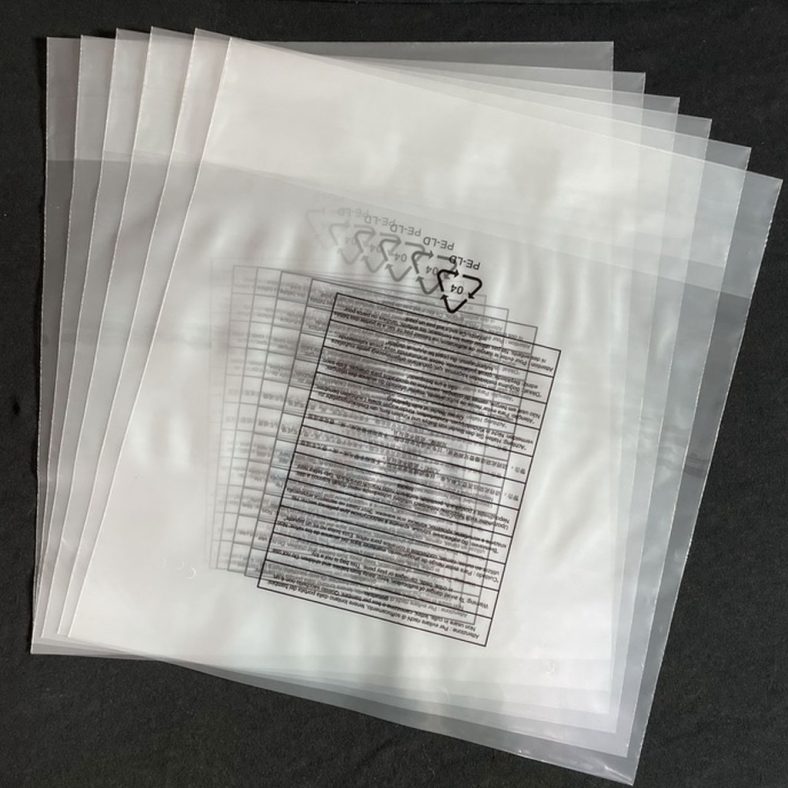

Transparent Flat Self-Adhesive PE Packaging Bags

-

3-5 Years Old Children’s Socks Packaging Bag

-

PE Organ Shape Bag For Textile Products

-

PE Organ Shape Bag For Clothing

-

Packaging Bag For PET Grooming Glove

-

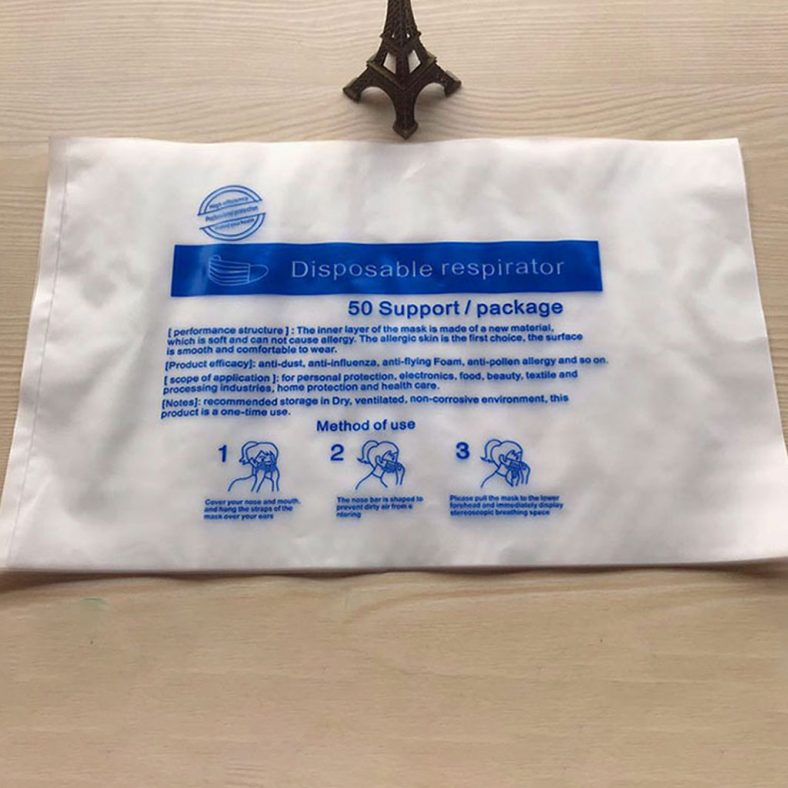

Medical Packaging Bag For Disposable Respirator

-

Packaging Bag For KN95 Protective Mask

-

Medical Cold Compress Packaging Bag

-

Single-Use Medical Mask Packaging Bags

-

Custom Flat Window Bone Bag For Medical Mask Packaging

-

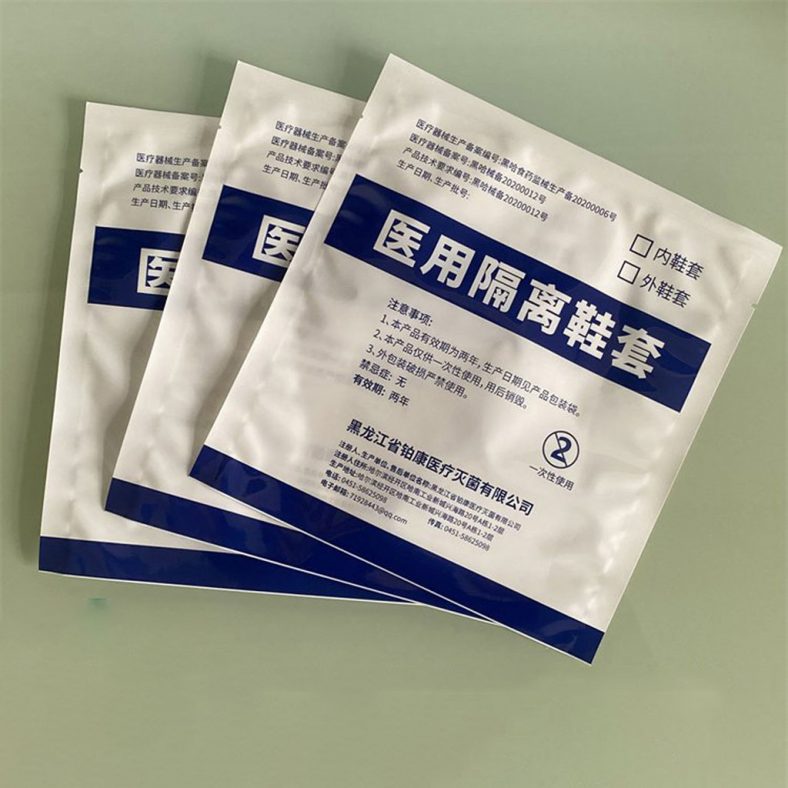

Self Sealing Bag For Medical Shoe Cover

Everything you need to know to make an informed decision about what poly bag or plastic film product is right for your application. We share information, tips and things we've learned from our years in the plastic bags manufacturing industry.

-

The Advantages Of High-Density Polypropylene Container Bags

-

Unveiling the Enduring Longevity of Ton Bags

-

Understanding the Causes of Uneven Surfaces in Ton Bags

-

Exploring the Art of Sewing Container Bags: Techniques, Methods, and Creativity

-

Precision Spun Musical Drum Kit Packaging

-

What Is Molded Pulp? An In-Depth Exploration of Eco-Friendly Packaging Solutions

-

The Main Role Of Sealing Tape

-

How To Make Plastic Bags Look More Beautiful?

Chaozhou Wonder Plastic Inc is a professional company dedicated to the research and development, production and sales of industrial packaging plastic bags and food packaging plastic bags. Established in 2002, the company is located in the new area of Anbu Town, Chaozhou City, Guangdong Province, with superior geographical location and convenient transportation.

Wonder Plastic has a professional management elite team with a group of high quality talents in R&D, production, quality management and marketing. Since its inception, Wonder Plastic has become a reliable partner for new and old friends in the industry. The company's plastic bags are made of PP, PE, PO, OPP, PPE, CPE, PVC, POF and other materials. Our products are widely used in many fields such as hardware, plastic, toys, crafts, electronics, garments, ornaments, materials, chemicals, textiles, etc. We can design and produce all kinds of packaging bags according to customers' requirements.

The company's existing plant area of nearly 8000 square meters, the existing equipment: 15 sets of film blowing machine, 22 sets of bag cutting machine, offset printing machine 5 sets, eight-colour computer high-speed copper printing machine 1 set, high-frequency wave voltage machine 20 sets, punching machine 4 sets, these equipment can be made for you to produce a variety of industrial packaging plastic bags, a one-stop production to reduce production costs, exquisite printing is the icing on the cake for your products!

Quality is the basis of our factory, quality and reasonable price make us stand in the fierce competition today, the company to high-quality products to meet the promise, to quality in return for care. We warmly welcome your visit and guidance!

Place your order, request a quote, or send us a message with any questions you might have. We help you avoid the pitfalls to deliver the quality and value your poly bag need, on-time and on-budget.